Tapout.

#1

Tapout.

I was replacing the fork seals when I ran in to this problem with the axle. Seems the last ******* that changed the tire did not put in the left side collar, so when they put the axle back on, the nut compressed on to the axle instead of tightening on to the forks. I used a 5 foot breaker and an impact wrench with a 1.25 # hammer and STILL could not get it off. The only thing that I could do was to improvise. I've had alot of questions on how to tap out stuck bolts. This is one method that can be applied to many applications. Here it is:

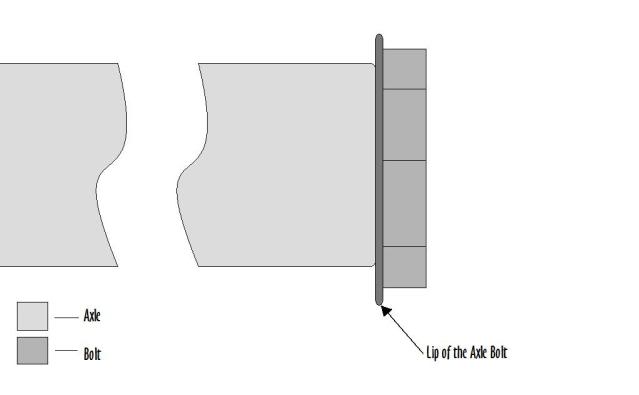

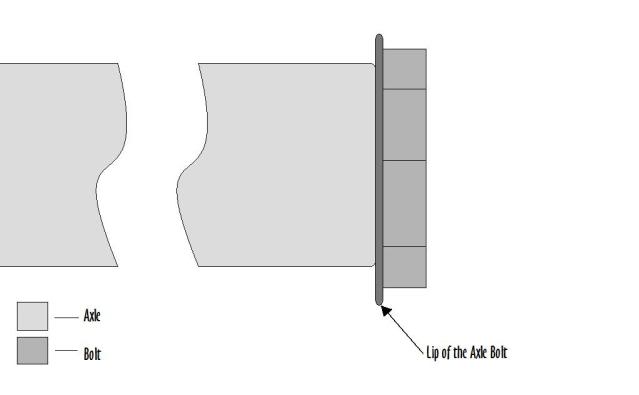

I could not take pictures with enough detail, so I made a diagram. Don't laugh:

Step 1: Usally you can skip to step #2, but with the extrem pressure tha is on the threads, you cannot just use a tapout. You need to first relieve the pressure on the threads. Take a grinder and shave off the bolt to where the lip meets the axle. If you do this carefully enough, you can salvage the axle. Once the bolt is gone, the diamater is small enough where you an get the axle out of the forks and remove the wheel.

Notice how it is flush. There is no more head to the bolt, therefore, the tension is relieved from the threads.

Step 2: Drill a hole in the middle that fits the diameter of the tap out that you have chosen:

Using the tapout, take out the threads.

The axle was not damaged, cuz’ I’m so fuc*ing good. However, the threads did need to be cleaned and the grinding damaged the first rung of threads. The best thing to do is use a tap to repair the damaged threads and clean out the remaining threads. Make sure you put cutting oil on your tap:

Now a new bolt fits like a glove!!

I could not take pictures with enough detail, so I made a diagram. Don't laugh:

Step 1: Usally you can skip to step #2, but with the extrem pressure tha is on the threads, you cannot just use a tapout. You need to first relieve the pressure on the threads. Take a grinder and shave off the bolt to where the lip meets the axle. If you do this carefully enough, you can salvage the axle. Once the bolt is gone, the diamater is small enough where you an get the axle out of the forks and remove the wheel.

Notice how it is flush. There is no more head to the bolt, therefore, the tension is relieved from the threads.

Step 2: Drill a hole in the middle that fits the diameter of the tap out that you have chosen:

Using the tapout, take out the threads.

The axle was not damaged, cuz’ I’m so fuc*ing good. However, the threads did need to be cleaned and the grinding damaged the first rung of threads. The best thing to do is use a tap to repair the damaged threads and clean out the remaining threads. Make sure you put cutting oil on your tap:

Now a new bolt fits like a glove!!