Stuck Buckets

#1

Stuck Buckets

My bike was making awful valve slap noise and the rear exhaust valves were at .026. I assume I accidentally switched the buckets when I was doing the valves over the winter. Now they are stuck. Really stuck. I tried a heat gun, I tried dry ice (did you know you can freeze oil to an immobile sludge?) I tried magnets and wd40. Does anyone have any good ideas on how to get them out without destroying anything? Do they oil from underneath somewhere where I could get air pressure in there?

#2

is it the buckets or the shims that are stuck?

Could you drill small holes and run some safety wire in a U shape through them and pull them out?

I really don't know what might help as I haven't shimmed the valves on my bike myself yet. (though I need to check them, and should just do it rather than pay for it)

Could you drill small holes and run some safety wire in a U shape through them and pull them out?

I really don't know what might help as I haven't shimmed the valves on my bike myself yet. (though I need to check them, and should just do it rather than pay for it)

#4

worst case is you take it to someone with a tig welder and they weld a screw onto it so you can thread a slide hammer onto it and then hammer the sucker out of there, you would of course need a new bucket but if done right would prevent needing a new head.

#6

Well there is nothing under them except for the valve guide.

The best bet would be find a rare earth magnet (one of the really strong ones) some good penetrating oil, then get the head as hot as you can. If they don't come out then welding is about your only option but the heads might also be damaged at this point.

The best bet would be find a rare earth magnet (one of the really strong ones) some good penetrating oil, then get the head as hot as you can. If they don't come out then welding is about your only option but the heads might also be damaged at this point.

#10

If the bucket is stuck, then it is probably wasted anyway. They are precision parts that you do not want to take a chance on failing, or causing a failure on other parts. I would not worry about damaging the bucket further, but I would be concerned about wasting anything else in the process of removing it. If a strong magnet does not work, the welding method is probably the safest. Rough up the surface first to help with the weld. JB weld might work, same thing, rough up the surface first. In any event, I would not reuse that bucket. It would make for an interesting shot-glass. JB

#11

I have a rear head in the freebies section with bent exhaust valves. It still has buckets, shims, cams, etc intact. Your more than welcome to it.

BTW I'm an hour and a half north east of you.

BTW I'm an hour and a half north east of you.

Last edited by psyclown; 03-25-2010 at 06:57 AM.

#14

Hardened steel shims floating around an engine is an invitation to disaster.

Unless you forgot them in the first place.........

Kai Ju

#15

I had it running for probably a total of a half hour so I'm assuming by the lack of catastrophe there not in the motor. There's no way they could have gotten out from under the buckets so I'm assuming that I'm the worlds biggest idiot and didn't put them back in. But yeah I thought of that and ran a magnet everywhere I could reach just in case.

#16

Be careful with the magnets. In the airplane world we do not use magnets in engines. If you even slightly magnatize a lifter, then all the tiny ferrus particals in the oil are atracted and cam wear is increased. While I know that the hawks cams are not as critical or expensive, it is just good practice.

#17

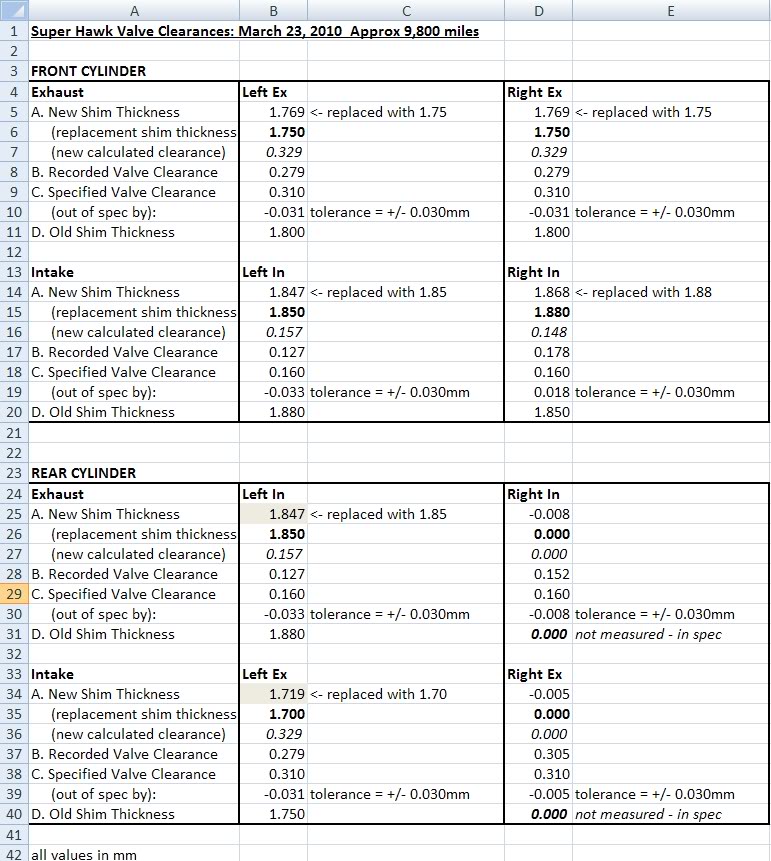

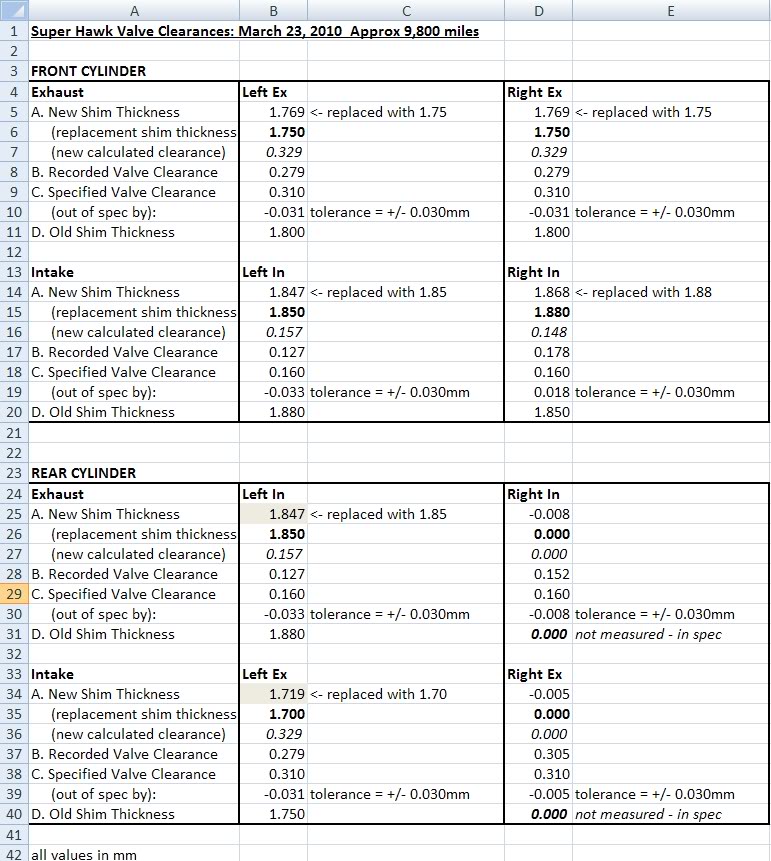

I just did my valves, and each shim was stuck to the bottom of the bucket when I lifted it off. I do the valves one at a time so as not to confuse myself (which is pretty easy to do). I use an xls to calculate shim sizes:

#18

I agree mhaisten but I'm pretty sure the manual recommends magnets and they have to be a lot better that the jb weld I ended up using. I cant believe the stuff stuck to those polished surfaces. I just cleaned with a bit of alcohol and liberally applied jb quick and a bolt. If the buckets weren't slightly scratched and mushroomed from valve slap I could still use them the jb comes right off with heat.

#19

They're not stuck to the bottom of the lifters, that's where I looked second. I'm also very disorganized but usually just lay the parts out in order. I use an online shim calculator and or calipers. By the way I'm sure you didn't do it in real life but you have your valve clearance specs backwards for your rear cylinder.

Last edited by spladle160; 03-26-2010 at 10:51 PM.

#20

Holy crap!! You gotta stop getting stoned before you work on your bike!

Even if you did forget the shims, you should ALWAYS check the clearance after installation.

I guess I don't need to say any more. Check your lifter bores before you go buying new lifters.

Even if you did forget the shims, you should ALWAYS check the clearance after installation.

I guess I don't need to say any more. Check your lifter bores before you go buying new lifters.

#22

+1 on mhaisten's advise.

The manual may say to use a magnet, but what works even better, without magnetizing the bucket, is a valve lapping tool with a suction cup.

What works in a pinch is a socket slightly smaller than the bucket.

Use the ratchet side, lightly coat with oil and stick it to the bucket. The oil film will make the bucket stick to the socket and you can lift it out. Make sure it's clean before you use it. If it takes more force than that you got a problem with either the bucket or the head.

Kai Ju

The manual may say to use a magnet, but what works even better, without magnetizing the bucket, is a valve lapping tool with a suction cup.

What works in a pinch is a socket slightly smaller than the bucket.

Use the ratchet side, lightly coat with oil and stick it to the bucket. The oil film will make the bucket stick to the socket and you can lift it out. Make sure it's clean before you use it. If it takes more force than that you got a problem with either the bucket or the head.

Kai Ju

#23

I swear I checked the valves after I adjusted the shims, the worst part is according to my notes those valves were never out. I don't think a valve lapping tool or oiled socket would have gotten them out since they were as the thread states STUCK, as in huge clearance due to no shims and being beaten by the cam. Luckily psyclown is a great guy and had a head with 4 bent valves that he let me have. I took the buckets from that got the right shims and now she runs great. As for being stoned, not my style. working while far to tired is more likely and I suspect at least as dangerous.

#25

I swear I checked the valves after I adjusted the shims, the worst part is according to my notes those valves were never out. I don't think a valve lapping tool or oiled socket would have gotten them out since they were as the thread states STUCK, as in huge clearance due to no shims and being beaten by the cam. Luckily psyclown is a great guy and had a head with 4 bent valves that he let me have. I took the buckets from that got the right shims and now she runs great. As for being stoned, not my style. working while far to tired is more likely and I suspect at least as dangerous.

I force myself to walk away, if I'm in a rush. I'll come back to it when I don't have to be. The big exception to that was rushing to get ready for a track day and a short distraction. It was a very costly error - you got off easy!

I suggest leaving the job incomplete, if you are rushing it. Come back the next day and check your work, before you button it up.

I'm glad it all worked out for you.

#26

Jealous girlfriend not wife (and my female dog, she's super jealous of the hawk) but truthfully it's mainly my own desire to have it down for as little time as possible. I think your right about leaving it un buttoned and looking over it later, I can't tell you how often that would help.

Thread

Thread Starter

Forum

Replies

Last Post

ClevelandSuperhawkRumble

General Discussion

13

02-21-2007 12:19 AM

mdbuehler

General Discussion

3

02-05-2006 08:51 PM

not sure what happened but the buckets are dinged and I will need to replace them.

not sure what happened but the buckets are dinged and I will need to replace them.