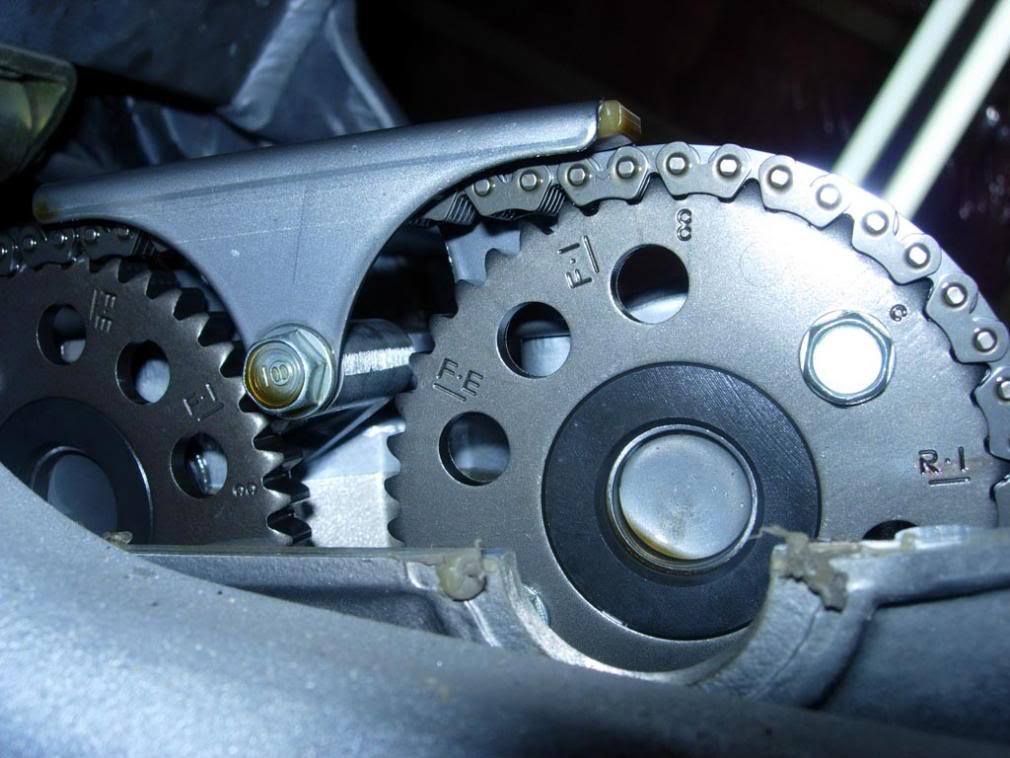

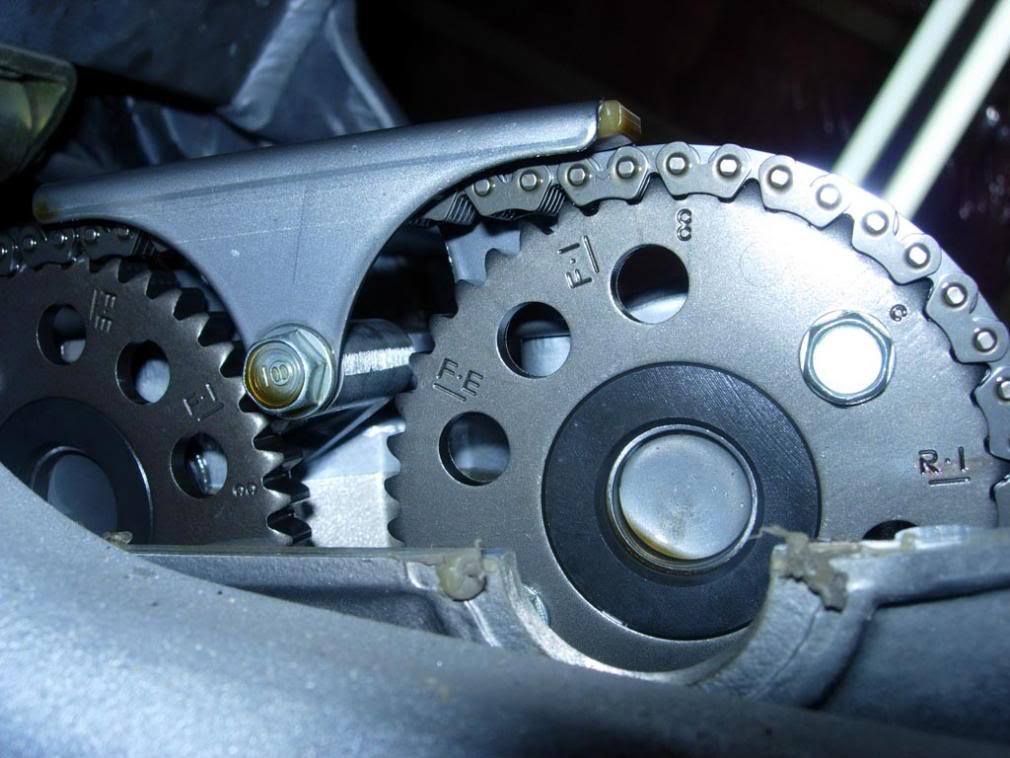

Misaligned cam sprocket marks

#1

Misaligned cam sprocket marks

So I've got my rebuilt heads on and the cams and cam sprockets on. The alignment on the rear sprockets is perfect, however the front ones don't line up exactly. If the crank is put at the FT mark the intake spocket is down about 2 degrees and the exhaust is up a couple degrees. I'm pretty sure if I move a tooth it will only make it worse. Is this common?

Another question as I was reassembling I was looking at the hose that runs along the front cylinder hear. It runs up through the plastic heat shield below the carbs and the other end exits through the frame above the left radiator. For the life of me I can't remeber what this connected to. I'm sure I'll find out as I reassemble, but meanwhile it's driving me nuts. Does anyone know what I'm talking about?

Another question as I was reassembling I was looking at the hose that runs along the front cylinder hear. It runs up through the plastic heat shield below the carbs and the other end exits through the frame above the left radiator. For the life of me I can't remeber what this connected to. I'm sure I'll find out as I reassemble, but meanwhile it's driving me nuts. Does anyone know what I'm talking about?

#2

what was done to your heads? were they milled at all?

in the shop manual early in the book are the diagrams for hose routing of all types and you should be able to find it their. I can look at mine later - off the top of my head I don't recall what is there under the carbs except the radiator thermostat hoses and the overflow hose for the radiator.

in the shop manual early in the book are the diagrams for hose routing of all types and you should be able to find it their. I can look at mine later - off the top of my head I don't recall what is there under the carbs except the radiator thermostat hoses and the overflow hose for the radiator.

#3

Not milled just lapped and all new valves on the front head. The rear head was just cleaned up lapped and reassembled. I talked to my mechanic and he assures me that slight variations from parallel are not uncommon. Nothings hitting or anything. So, I guess I'll continue rassembly. I just dread the thought of having to take it apart again. I've already worked on it forever and have a long way to go. At least it's got Apes in it now.

#5

Duh, the hose is the crankcase breather turned around backwards.

As for the slack I have the apes tightened down. My mechanics point was that all of those spockets are the same. Being a mass produced stamped item the tolerances may not be great.

It's too cold out to deal with it right now anyway, but I think I just need to stop being paranoid and put the covers on.

As for the slack I have the apes tightened down. My mechanics point was that all of those spockets are the same. Being a mass produced stamped item the tolerances may not be great.

It's too cold out to deal with it right now anyway, but I think I just need to stop being paranoid and put the covers on.

#6

You can try to make it skip a tooth to see if it gets worse, Just go for the best setting, mine don't quite line up perfectly as well. Give some slack and pull the chain to add an extra link on the sprocket, then push it around the sprocket with your finger, it works wonderfully, you may have to remove the chain guide but at least you save the sprocket disassembly.

Thread

Thread Starter

Forum

Replies

Last Post