Front cylinder may not be firing.

#31

EDIT: Feeler gauges found. Interesting findings for sure...

Exhaust: Both .30 mm, set to spec.

Intake: .15mm and... .23mm. uh oh. Why I didn't set this correctly first is beyond me haha! Still, would this cause a compression leak? This just means that the valve is seating way too early, correct?

Exhaust: Both .30 mm, set to spec.

Intake: .15mm and... .23mm. uh oh. Why I didn't set this correctly first is beyond me haha! Still, would this cause a compression leak? This just means that the valve is seating way too early, correct?

#33

Did you say you'd been running a little rich? Another member had a low compression problem that turned out to be carbon deposits on the valve seats, if I recall correctly. That was about a year or so ago.

It might have been autoteach, but I'm not sure. You might want to search his thread history.

It might have been autoteach, but I'm not sure. You might want to search his thread history.

#34

Well the next set would be the wet compression test. Yes the one that you put some oil in the cylinder. What this does is help isolate the problem.

If the compression pressure rises the you have a problem with the rings.

If the compression pressure stays around the same, then you have a problem with the valves.

If the compression pressure rises the you have a problem with the rings.

If the compression pressure stays around the same, then you have a problem with the valves.

#35

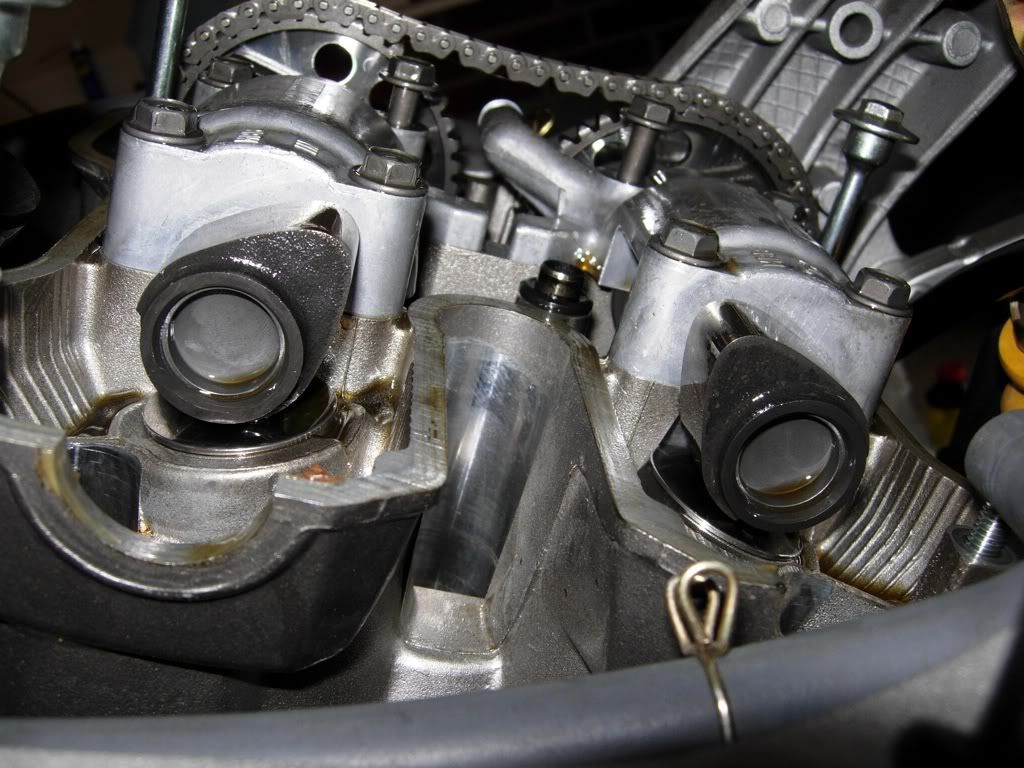

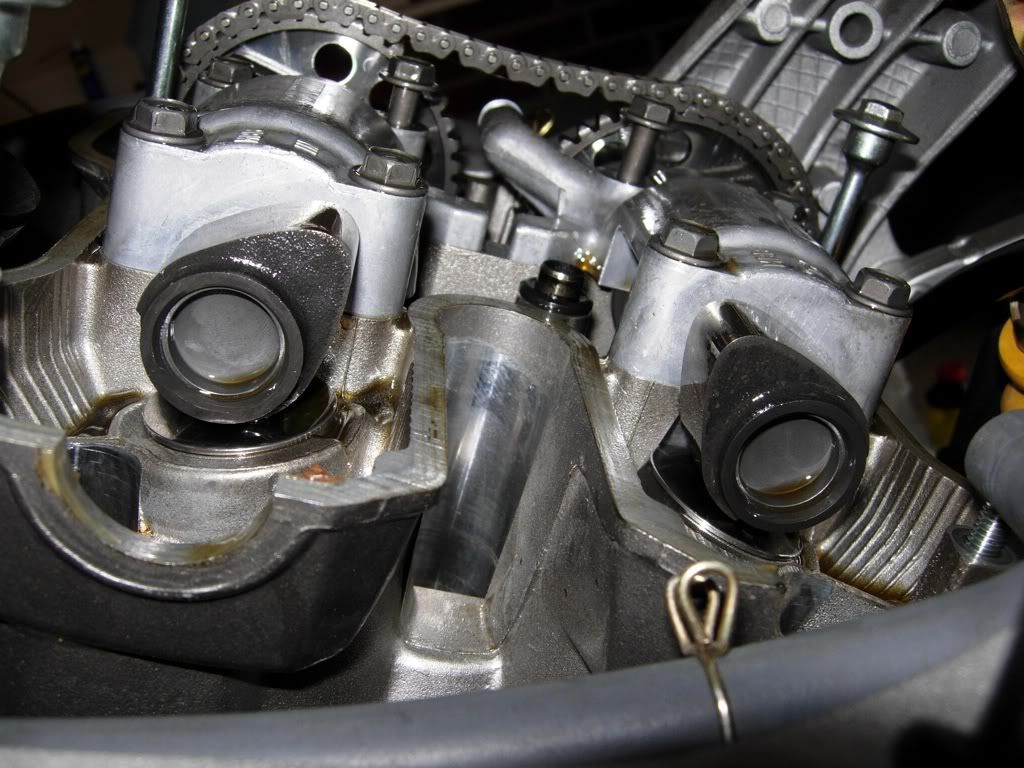

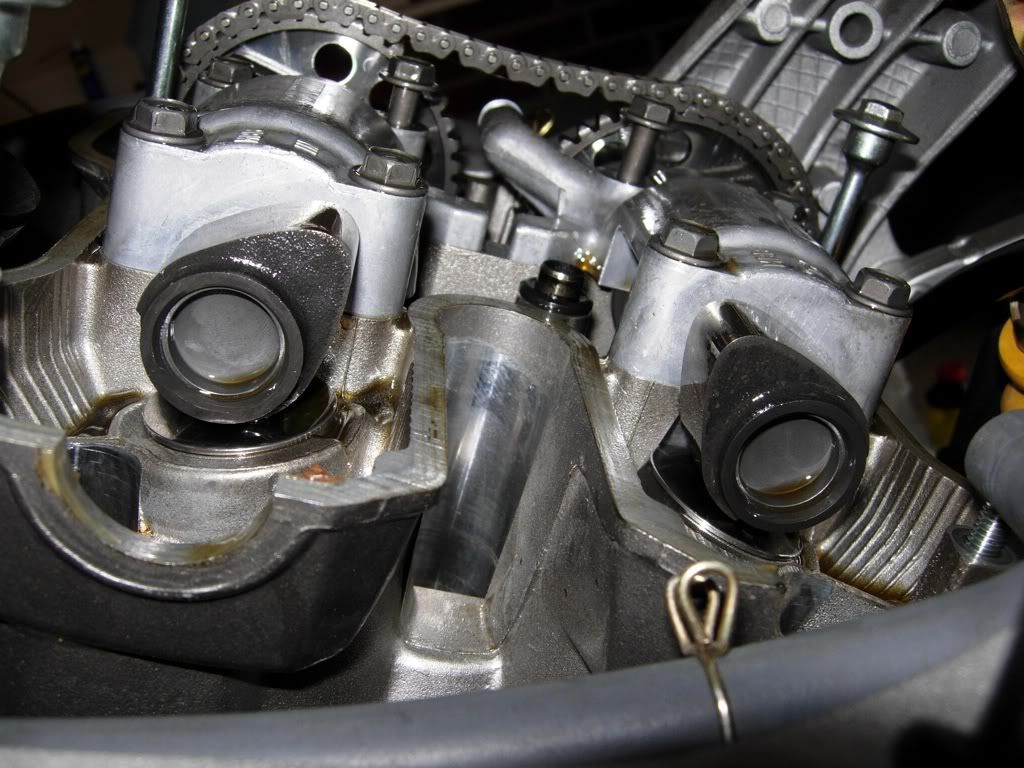

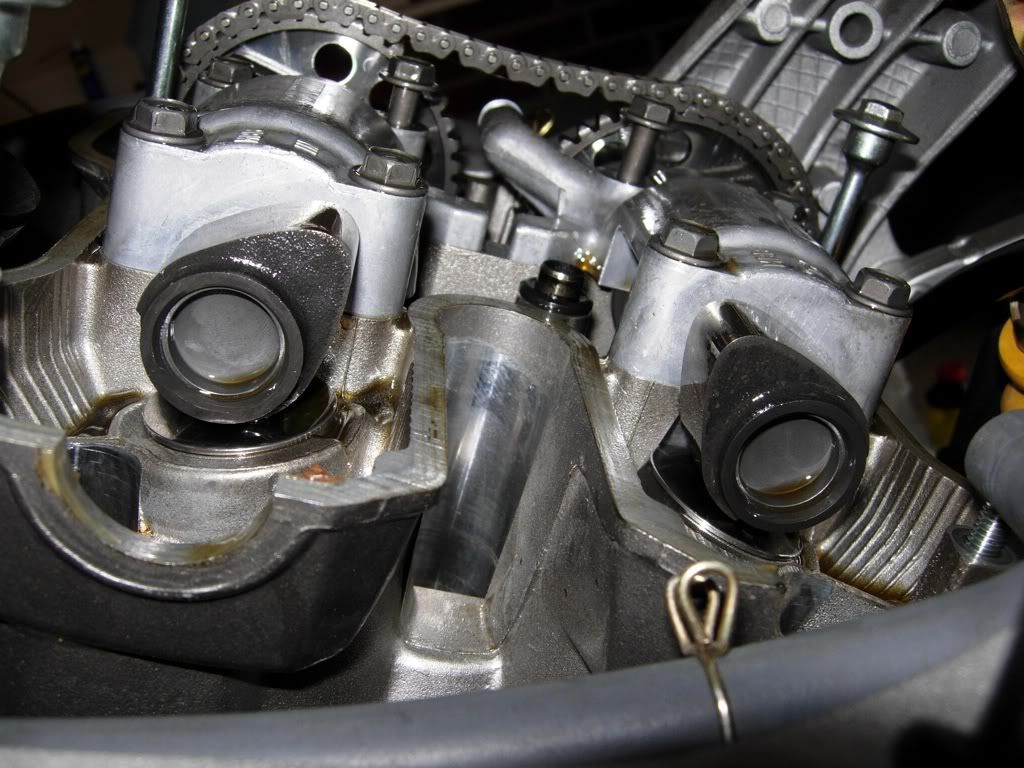

I thought the cams are supposed to look like this:

(image stolen from this thread: https://www.superhawkforum.com/forum...install-15184/ )

(image stolen from this thread: https://www.superhawkforum.com/forum...install-15184/ )

#36

#37

I thought the cams are supposed to look like this:

(image stolen from this thread: https://www.superhawkforum.com/forum...install-15184/ )

(image stolen from this thread: https://www.superhawkforum.com/forum...install-15184/ )

They are supposed to look just like that. I just pulled mine out and re-installed them to reset the timing. It was pretty easy, just pull the guide off, loosen the cam guides/holder bolts evenly across all three bolts on each cam guide, wire the cam chain to the subframe or something, pull your CCT and then holding the chain up remove the cam's with the cam gears still attached, set those aside, (your RT mark should be lined up with the knock) and since I didn't know where my piston was re spun the engine one full turn back to RT and then replaced the cams so the RI and RE we lined up with the lip of the head, align so once tension applied the RI and RE are where they need to be, and then reinstall your CCT. That is if you don't know where your piston is and you're trying to reset your timing.

It sounds like something's way off however with your compression. I think you've already done the wet compression test and determined it wasn't the rings but your gasket?

According to my text book "Loss of compression results in hard starting, loss of power and possible wet or fouled plugs." So your compression in the cylinder that's running better than the other but is still wetting your plug is also indicating that compression in that cylinder isn't where it needs to be, sounds like both cylinders are having compression issues...

If you haven't done the wet compression test, "add a small amount of clean engine oil into the cylinder and recheck the compression readings. If compression increases to more than the previous reading, inspect the cylinder and piston rings. If compression remains low, check the valves, valve seats, and cylinder head. Other possible causes of low or uneven cylinder compression are;

-Faulty valve mechanism

-Incorrect Valve clearance

-Bent, burned, or sticking valves

-worn or damaged valve seat

-Incorrect valve timing

-Broken valve spring

-Faulty hydraulic valve adjuster

-leaking or damaged head gasket

-warped or cracked cylinder head surface

-worn or damaged piston rings

-Worn Piston or cylinder

-piston ring stuck in ring groove

So I wouldn't run out and buy a new head gasket just yet unless there's other indications of a head gasket failure, like milky oil... Check the list above first and cancel out any that are not an issue. I bet you find what's wrong going through part by part... Anyway, hope that helps a bit, I'll check back after class...

Blink

#38

Could be any of these:

-Faulty valve mechanism

-Incorrect Valve clearance

-Bent, burned, or sticking valves

-worn or damaged valve seat

-Incorrect valve timing

-Broken valve spring

-Faulty hydraulic valve adjuster

-leaking or damaged head gasket

Probably not due to wet compression test:

-warped or cracked cylinder head surface

-worn or damaged piston rings

-Worn Piston or cylinder

-piston ring stuck in ring groove

Pretty sure to do anything valve related, I need to get a new head gasket anyway

#39

EDIT: Feeler gauges found. Interesting findings for sure...

Exhaust: Both .30 mm, set to spec.

Intake: .15mm and... .23mm. uh oh. Why I didn't set this correctly first is beyond me haha! Still, would this cause a compression leak? This just means that the valve is seating way too early, correct?

Exhaust: Both .30 mm, set to spec.

Intake: .15mm and... .23mm. uh oh. Why I didn't set this correctly first is beyond me haha! Still, would this cause a compression leak? This just means that the valve is seating way too early, correct?

Well for the lash to open up would mean the valve isn't seating back into the head for some reason.

So no the valve isn't closing early, more likely it is being held off the seat by something, which would cause a compression leak.

#40

Hypothesis: plane ole carbon buildup! Let's test it later this evening!

Edit: By heads I meant top engine cases haha

Last edited by 7moore7; 03-21-2011 at 01:57 PM.

#41

Though at this point it would be a good idea to pull the head and figure out what is happening.

#42

Yep, same side and all- that's actually the only reason I'm saying it's the left intake one causing problems. Just figured I'd give a hypothesis for kicks before I open it up. It'd be cool to get in there, see it not seating correctly, and going, "yep- that's what we kinda figured"

#43

Before you pull the head off try pulling the carbs off and peeking down the intake hole. Rotate the motor to where the cams open the intake valves to get a good look at the seating surface.

#44

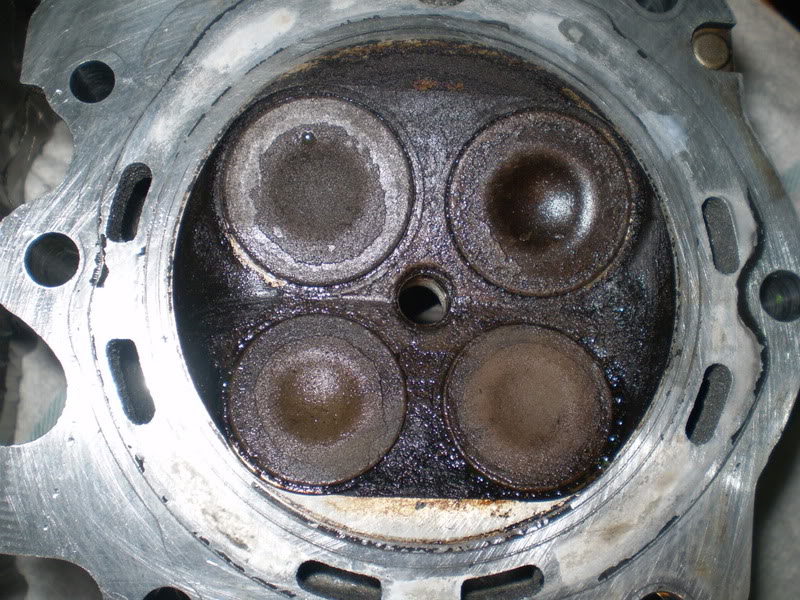

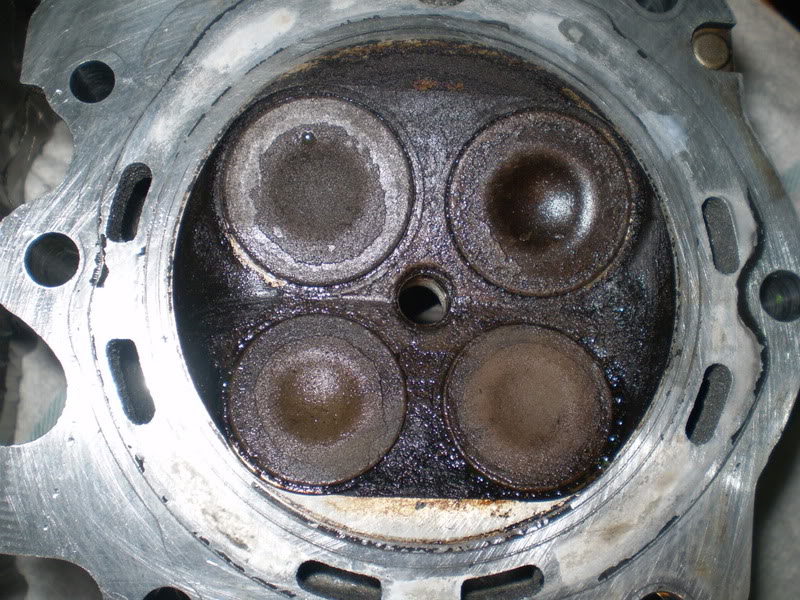

Too late:

Bottom right was the suspect if there is one I think I need a valve spring clamp. I'll probably go ahead an remove the rear head while I'm doing all of this.

I think I need a valve spring clamp. I'll probably go ahead an remove the rear head while I'm doing all of this.

P.S. no where was I told that it would pee coolant all over the place!

But noob, that would probably have been a good idea as now I can't inspect the surface without a clamp or something...

Bottom right was the suspect if there is one

P.S. no where was I told that it would pee coolant all over the place!

But noob, that would probably have been a good idea as now I can't inspect the surface without a clamp or something...

#46

#47

Gonna take the heads to mechanic tomorrow- he'll help me get the springs out, see if the valves are seating properly, possibly re-cut the valve seats, clean all the carbon off, talk motorcycles...

It was difficult to tell if the WD-40 leaked through... again, something to be assessed by an experienced eye tomorrow!

It was difficult to tell if the WD-40 leaked through... again, something to be assessed by an experienced eye tomorrow!

#49

Hahaha, yep lazn you hit the nail on the head. What started as a simple frame replacement turned into a whole thing... it's good have the Shadow to putt around on or I'd go nuts...

I also haven't been inside the forks yet...

Financially hasn't been the best move either This forum is just like taking a motorcycle class though and it's totally worth the entertainment value.

This forum is just like taking a motorcycle class though and it's totally worth the entertainment value.

I also haven't been inside the forks yet...

Financially hasn't been the best move either

Last edited by 7moore7; 03-21-2011 at 11:16 PM.

#51

Hell why your in there this deep after the valves are out give those intake and exhaust ports a qick touch with a dremel and a flapper wheel. Remove all those nasty casting marks. Then cut new seats touch up the valve faces and lap in the valves.

#52

Exactly what I was thinking as I have to wait for head gaskets anyway...

Gonna have a pro do the seats and fix the faces. But a port and polish homemade edition might be in order. Any recommendation for cleaning the cylinder heads while they're still in the motor? I was just thinking scotchbrite and minerals spirits...

Gonna have a pro do the seats and fix the faces. But a port and polish homemade edition might be in order. Any recommendation for cleaning the cylinder heads while they're still in the motor? I was just thinking scotchbrite and minerals spirits...

#54

7moore7,i just wanna thank you for all you are doing,i think i will be able to do alot to my bike now and skip some mistakes and fumbles lol

I've kept track of all your progress and it will be very helpfull..just maybe i wont have to ask to many questions

I've kept track of all your progress and it will be very helpfull..just maybe i wont have to ask to many questions

Thread

Thread Starter

Forum

Replies

Last Post

niteridder64

Technical Discussion

9

03-21-2013 02:42 PM