Turbo Build

#35

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

Thanks a lot for the comments, I found some time to start planning to splice wires and I think that I will be able to use the stock ignition driver (the 6 wires box), so using Microsquirt on a logic level will cause less problems due to flyback current (false tach, processor reset, etc...)

For the hardware I'm waiting for some heat wrap, boost gauge and a 90" AN-10 fitting since I don't like how close my oil return comes from my rear tire.

For the hardware I'm waiting for some heat wrap, boost gauge and a 90" AN-10 fitting since I don't like how close my oil return comes from my rear tire.

#37

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

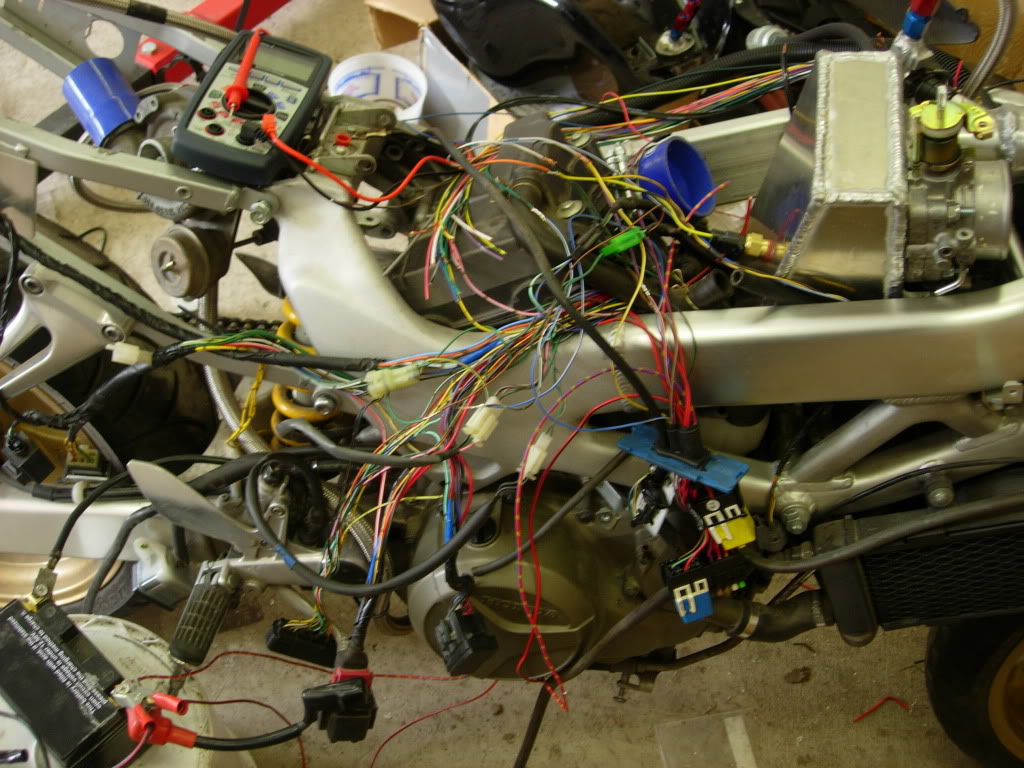

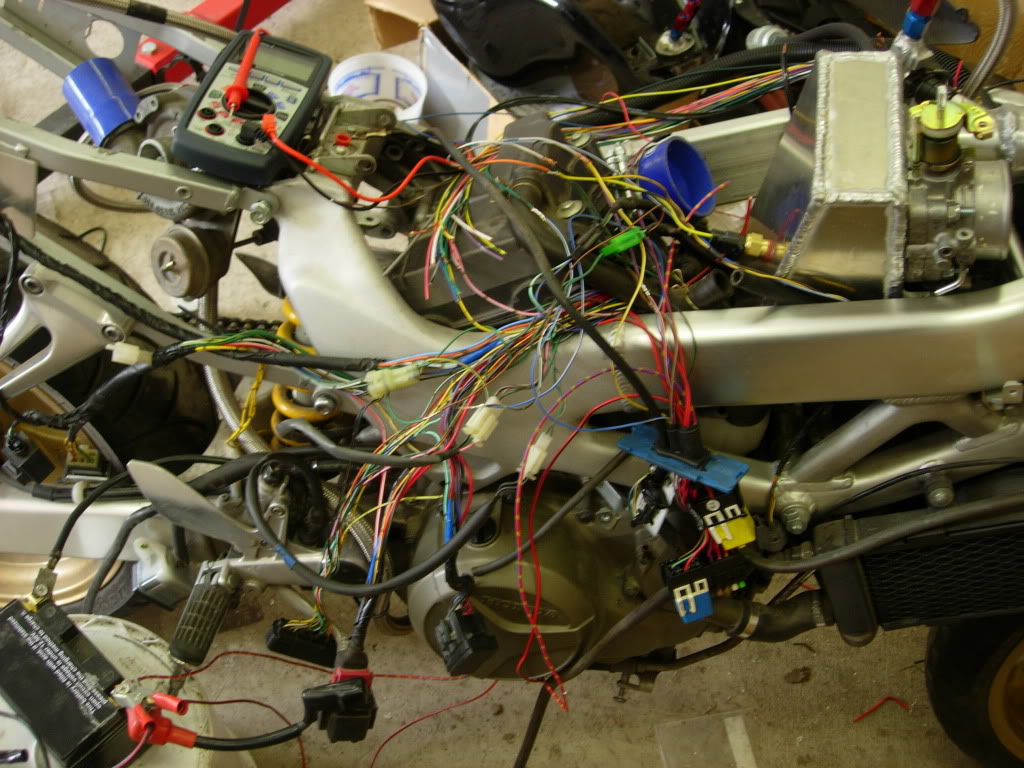

Good, I just established my first communication with the ECU trough a PC.

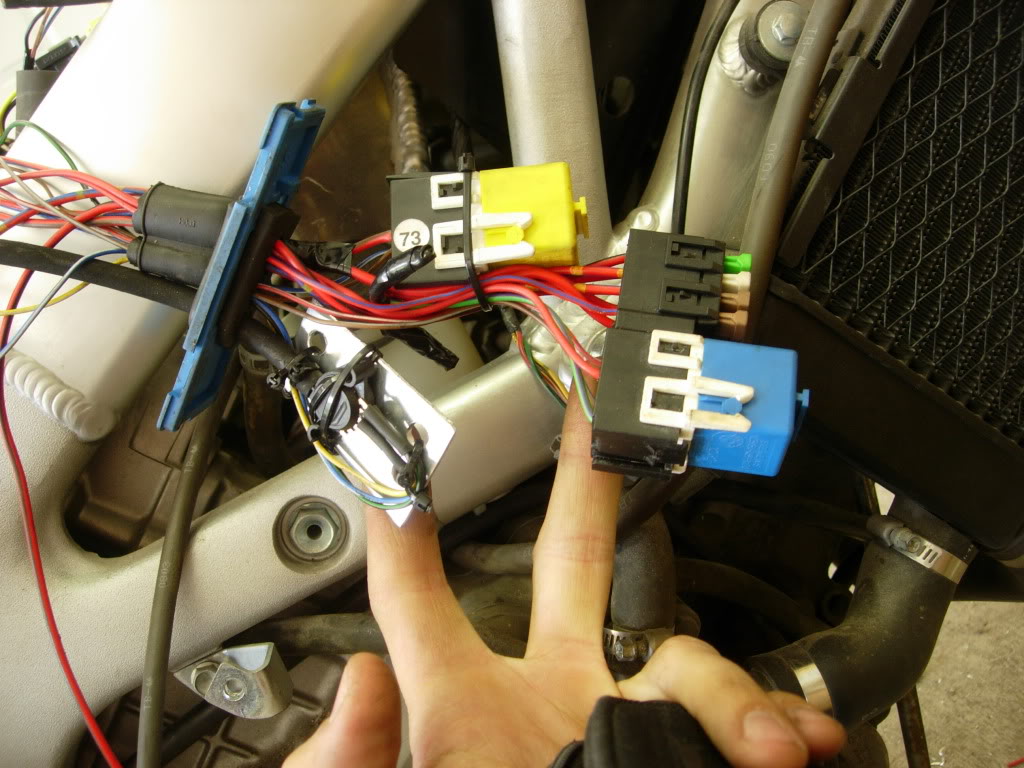

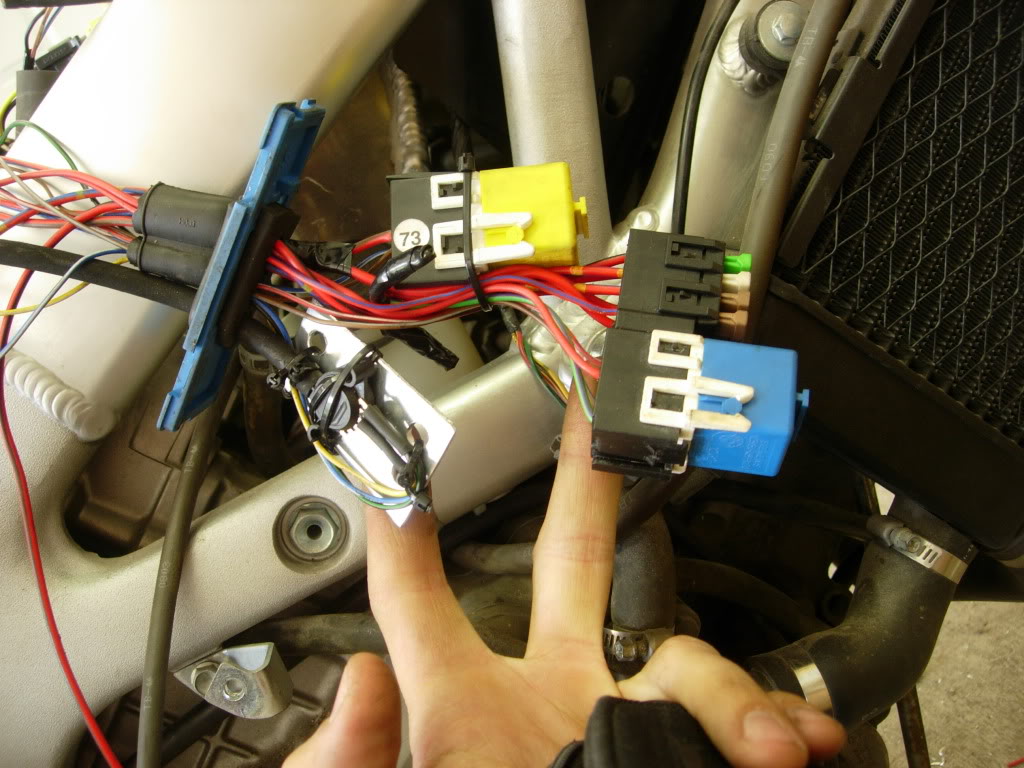

I made a relay box (not in it's box yet) to control the fuel pump, injector, O2 sensor, with a fuse box with parts from my parted out BMW.

I welded the lid of the airbox and pretty much finished the fuel side, tapped 3 vac ports.

Now I have Intake air temp, coolant temp, throttle position sensor and MAP sensor that works.

I had to go splice a 96 fiber cable last night from 9PM to 8 AM, that slows down a week end, now I'm going out for a week, I really wonder where is that damn recession.

I made a relay box (not in it's box yet) to control the fuel pump, injector, O2 sensor, with a fuse box with parts from my parted out BMW.

I welded the lid of the airbox and pretty much finished the fuel side, tapped 3 vac ports.

Now I have Intake air temp, coolant temp, throttle position sensor and MAP sensor that works.

I had to go splice a 96 fiber cable last night from 9PM to 8 AM, that slows down a week end, now I'm going out for a week, I really wonder where is that damn recession.

Last edited by gboezio; 06-07-2009 at 07:54 PM.

#41

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

Totally, even if there is some confusion sometimes, the manual wiring diagram is mandatory here.

It's a good way of learning your motorcycle electric system

Heat wrap in on the way, so I can finalize and bolt stuff together for good so it looks like a turbo bike.

Next step is to get tach, then get ignition, then injection pulse.

I will be able to help those who will want to fuel inject their bikes using this system, even if the fuel maps will not work for another setup (ITB's)

Ignition and the rest of the settings, wiring should be very similar.

I may be able to log on this week if the hotel have a computer with internet access.

#42

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

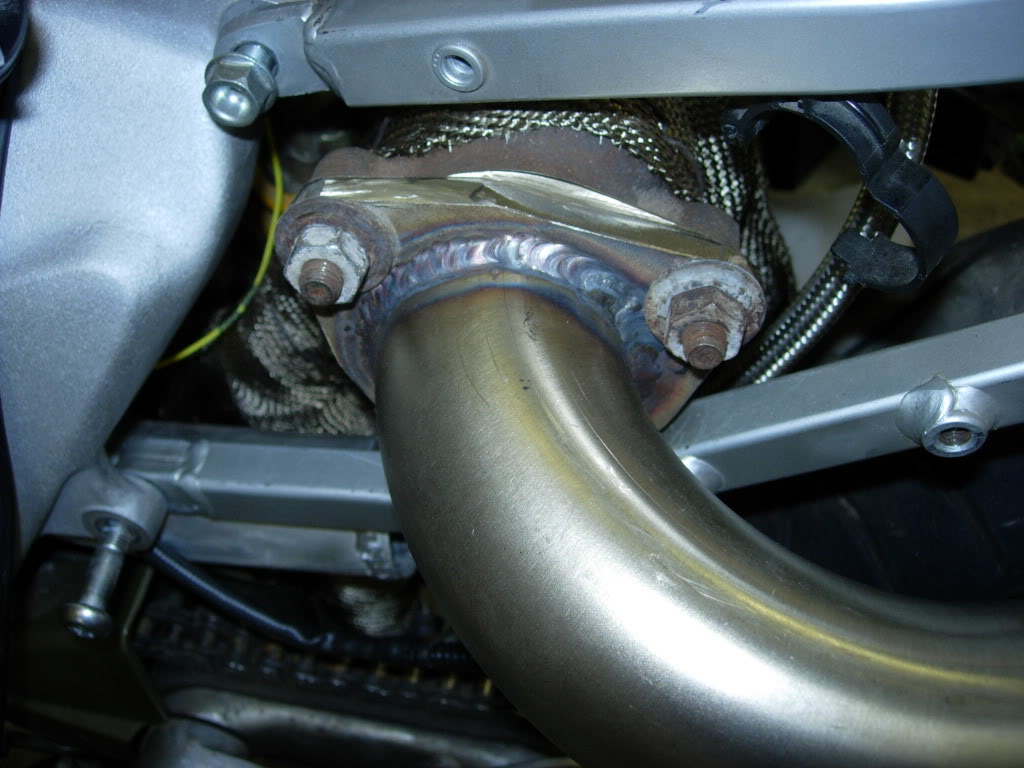

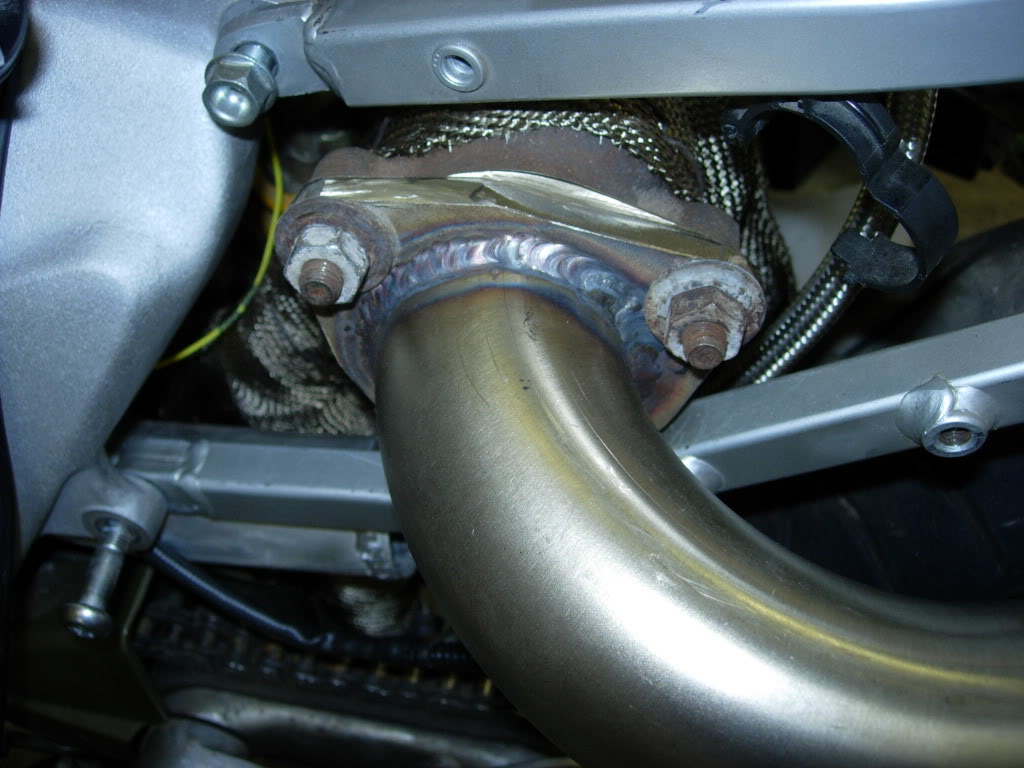

I had some time to work on my bike, this is the tough part, where all come together, flaws shows, in this case 2 oil leaks and 2 fuel leaks (all fixed), I had hell to set up the timing, the settings are not quite what I expected so I modified the settings until I had spark at TDC on both cylinders, I had a priming pulse set and I was truning the ECU on and off many times to reboot the unit while changing settings, when I fired up the unit the manifold blew right off the engine . Well no more priming pluse for me.

. Well no more priming pluse for me.

There's a lot of tuning left to get this thing running properly.

Here's a couples of vids

. Well no more priming pluse for me.

. Well no more priming pluse for me.There's a lot of tuning left to get this thing running properly.

Here's a couples of vids

Last edited by gboezio; 06-21-2009 at 06:58 PM.

#49

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

Thanks a lot for the comments, I still have some work to do, but it's comforting to know that it run at least, now I need to resume the fab work and make this thing rideable.

I datalogged the run time and I'm analysing the results to understand why it misfire past 2500 RPM, the dwell seem to take a plunge for some reason.

Doing this, you have to expect problems, you fix one, take on the next one, repeat, lol

I wish you could hear the turbine, I could hear it live but the movie sound clip it overwhelmed by the exhaust pulses

I datalogged the run time and I'm analysing the results to understand why it misfire past 2500 RPM, the dwell seem to take a plunge for some reason.

Doing this, you have to expect problems, you fix one, take on the next one, repeat, lol

I wish you could hear the turbine, I could hear it live but the movie sound clip it overwhelmed by the exhaust pulses

#53

Many have already seen this, but Mekanikker led the way...

http://www.youtube.com/watch?v=xjkkKGI0HR0

#54

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

Thanks for the comments

Motec is probably the best ECU I can think of, if I ever win a million and build a racing Porche or something like this I could consider it, but with a price tag of 5000 $ for the unit and the rights to use it (It's locked), the ECU will be worth more money than the bike itself, thias king of engineering come at a fair price.

Microsquirt is 400$ and all softwares are free, but it's DIY oriented, it need way more time to set up properly.

Here's the datalog I ran, the dwell is falling at 2500 rpm, this the next thing I will investigate there may not be enough time to fully charge the coils

I may have to change the coils for LS1 units if I don't find a way, I have a hard time understanding how they were fired by the ICU in the first place

why did you run that type of stand alone? why not a sds or motec? the sds would have been easier on the brain.

looks good though

looks good though

Microsquirt is 400$ and all softwares are free, but it's DIY oriented, it need way more time to set up properly.

Here's the datalog I ran, the dwell is falling at 2500 rpm, this the next thing I will investigate there may not be enough time to fully charge the coils

I may have to change the coils for LS1 units if I don't find a way, I have a hard time understanding how they were fired by the ICU in the first place

Last edited by gboezio; 06-22-2009 at 05:54 PM.

#55

awesome build! also great to see cool bikes are build in our part of the world! (I'm from st-jean-sur-richelieu )

)

keep on the great work, i'll follow your megasquirt too..

seems that you'll have the same problem as Honda runnign itb.. pulses from the map sensor. they usually build a reservoir ( a close tube with a hose leading to each throttle bodies and the map take it's signal from inside that tube. on a 4 cylinder it realy stabilise the signal. i dont know if it will help on the twin...

still, there is 2 solution, i think you can run megasquirt on alpha-N, ( mainly with tps signal. the map is used only to fine tune the mixture.. of you can run a maf..

or a bigger air-box will probably help at the cost of slightly less response at low rpm. but you'll probably gain some top end

keep on the great work, i'll follow your megasquirt too..

seems that you'll have the same problem as Honda runnign itb.. pulses from the map sensor. they usually build a reservoir ( a close tube with a hose leading to each throttle bodies and the map take it's signal from inside that tube. on a 4 cylinder it realy stabilise the signal. i dont know if it will help on the twin...

still, there is 2 solution, i think you can run megasquirt on alpha-N, ( mainly with tps signal. the map is used only to fine tune the mixture.. of you can run a maf..

or a bigger air-box will probably help at the cost of slightly less response at low rpm. but you'll probably gain some top end

Last edited by physician; 06-26-2009 at 01:03 PM.

#56

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

keep on the great work, i'll follow your megasquirt too..

seems that you'll have the same problem as Honda runnign itb.. pulses from the map sensor. they usually build a reservoir ( a close tube with a hose leading to each throttle bodies and the map take it's signal from inside that tube. on a 4 cylinder it realy stabilise the signal. i dont know if it will help on the twin...

still, there is 2 solution, i think you can run megasquirt on alpha-N, ( mainly with tps signal. the map is used only to fine tune the mixture.. of you can run a maf..

or a bigger air-box will probably help at the cost of slightly less response at low rpm. but you'll probably gain some top end

seems that you'll have the same problem as Honda runnign itb.. pulses from the map sensor. they usually build a reservoir ( a close tube with a hose leading to each throttle bodies and the map take it's signal from inside that tube. on a 4 cylinder it realy stabilise the signal. i dont know if it will help on the twin...

still, there is 2 solution, i think you can run megasquirt on alpha-N, ( mainly with tps signal. the map is used only to fine tune the mixture.. of you can run a maf..

or a bigger air-box will probably help at the cost of slightly less response at low rpm. but you'll probably gain some top end

MAF is not a bad setup, but it's slower than the MAP sensor, the ECU have a hard time to follow the fast rising signal of these small engines.

So far, the idle vacuum is not very high, it's idling around 75-80 kpa and the signal is still unstable, it cou.ld cover 5-6 bins on the table, butr it runs well

I may have to get the turbo rebuild, there's oil leakage on the compressor side, I will reduce the restrictor size to 0.035, I had 0.060 @ 60 psi, it should be 25-30 psi and go from there.

The Wideband O2 is working, I need to build the post turbo exhaust and I will get EGO readings.

#57

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

Update time !!

I think that I can start the final assembly, not much visual stuff have been done, I pretty much fixed all the problems, I have found why I had full lean readings trough my O2 sensor...damn PAIR system, I forgot about it existence.

The tune is barely started, but now that all systems works well it should go faster from now.

I still have some fab work to do and very little time.

To make a restrictor I tapped the fitting M6 and screwed a 0.30 MIG welder tip

I think that I can start the final assembly, not much visual stuff have been done, I pretty much fixed all the problems, I have found why I had full lean readings trough my O2 sensor...damn PAIR system, I forgot about it existence.

The tune is barely started, but now that all systems works well it should go faster from now.

I still have some fab work to do and very little time.

To make a restrictor I tapped the fitting M6 and screwed a 0.30 MIG welder tip

Very impressive work ! Like a "Mad Scientist " ! You gotta promise to post some video of this BEAST when you get it going . I will be checking this thread often ...I cant wait to see/hear it run

Very impressive work ! Like a "Mad Scientist " ! You gotta promise to post some video of this BEAST when you get it going . I will be checking this thread often ...I cant wait to see/hear it run