Turbo Build

#1

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

Turbo Build

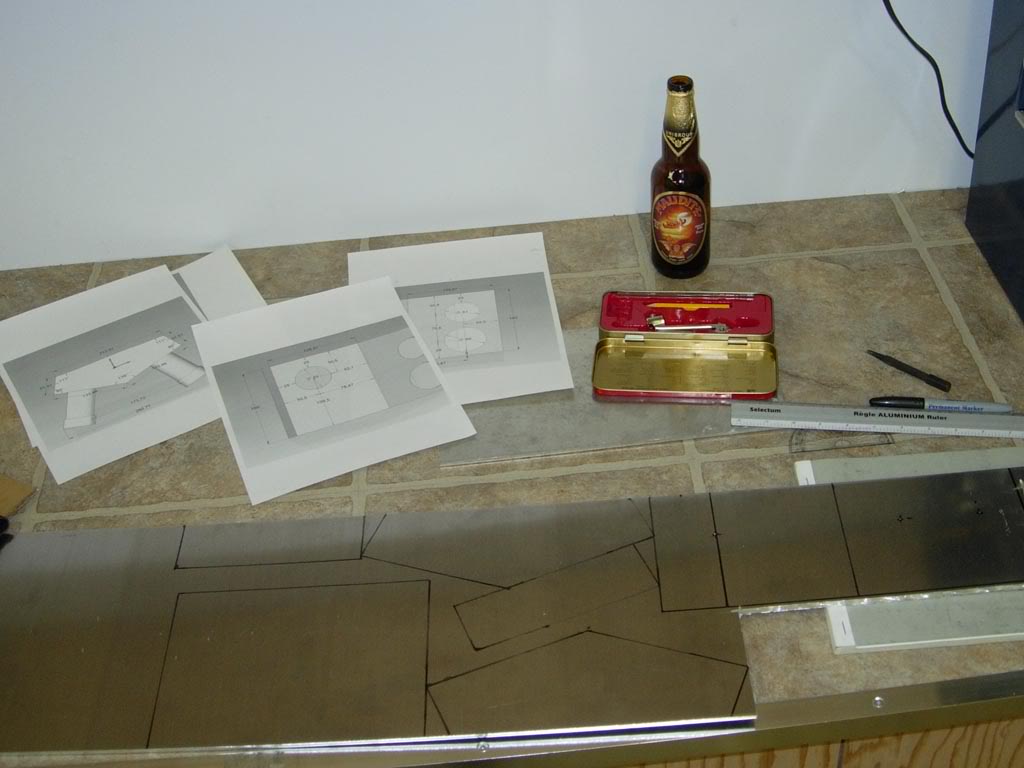

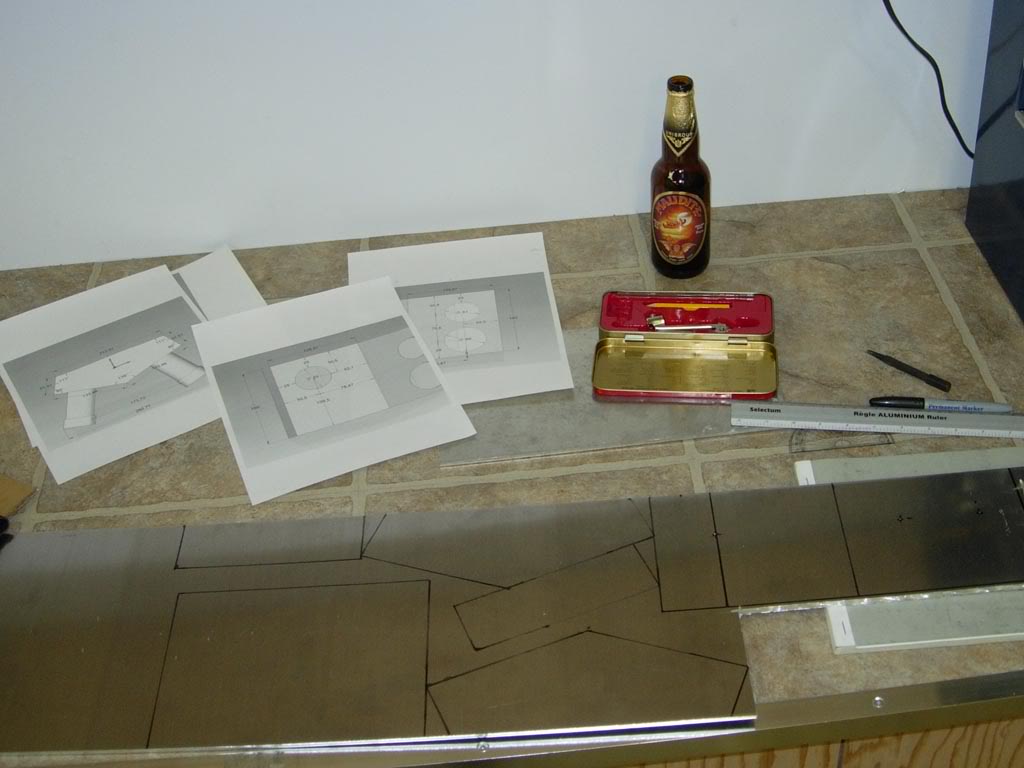

Well for some reason I suffered from post-phobia for this project, so I started this thread 3 times already in the past week, finally deleted it, get a beer and head to the garage.

I should have started an oil thread instead

We ran out of work from that market crash, the fiber optics networks got paralyzed by the banks shutting down big projects. So for a while I had plenty of time, some money and the garage is almost done (I'll finish next winter )

)

In the same time Quebec License dept, dropped the VTR to regular bikes and fee went from 1400 $ to around 5-600 $ and brought back some motivation.

Those who have modified a vehicle probably know that it always looks easier than it is, details are very time consuming and I want to do it right the first time, even if it's an open project, means that it have no end really and will change shape in the future.

My goal is a torque monster with no more horsepower than a CBR1000, but a full spool by 4000 RPM so the torque is not coming like getting rear ended by a racing granny.

It needs to be fun, it need to be build by me to my own specs, it need to be cheap and made using some junkyard parts, it need to looks as good as possible, but I'm a practical over bling type of person, I wash my bike twice a season.

I calculated mass flow, BSFC, VE and selected a Borg Warner K03 turbo for it's compressor map, price and availability, they are used on 1999 1.8 T Volks/Audi and support up to 180 hp worth of airflow.

I scored a 5,50$ intercooler on fleabay that I fitted to the rear of the bike, a custom unit could do better as a sleeper, but I don't mind the charge pipe that we see under the plastic.

Of course it will need to be fuel injected, I don't feel like blowing my motor, at least not before October for god's sake. At first I tried to use the carbs as throttle bodies, but I finally ditched the idea doing research on speed density on individual throttle bodies--->it sucks.

So I made an airbox that have the throttle before the plenum, I got a Datsun 240SX 60mm TB for a song.

I had the choice of buying parts for my bike or buying tools, I used what I had, but it took more brain matter, like my grinder/lathe to "machine" the bottom of the runners to fit the boots

This is the first version I made, the injector were too loose in it, so I bought for close to nothing a Malibu fuel rail and fuel pressure regulator that I chopped up in pieces, the last version is the last picture

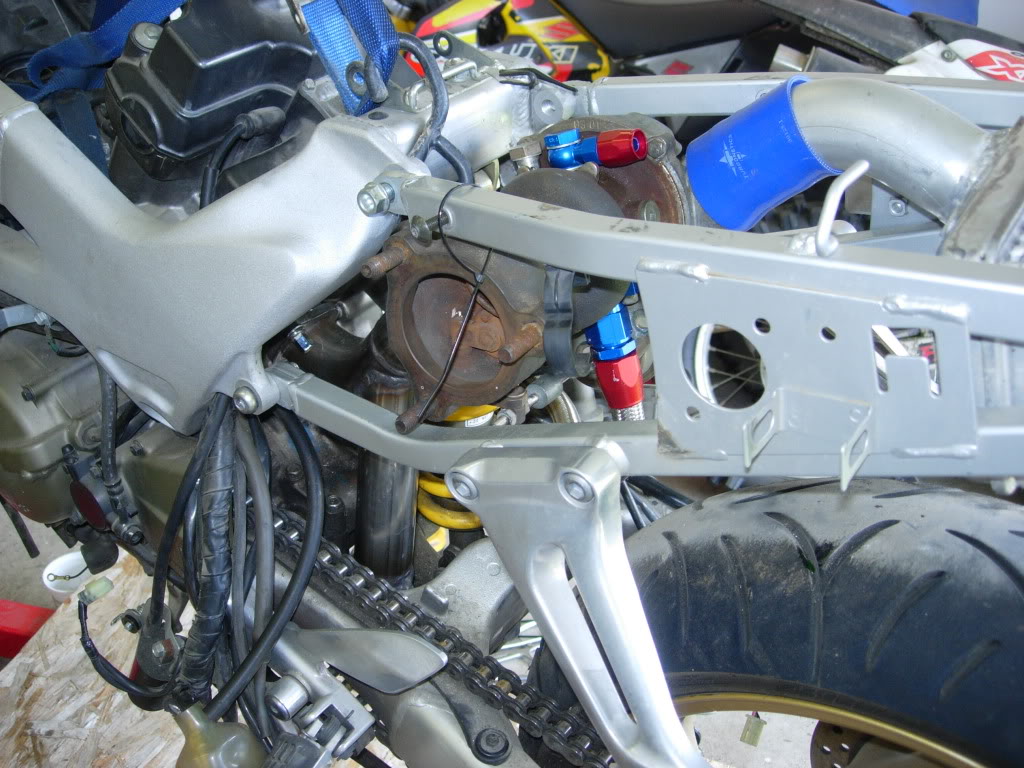

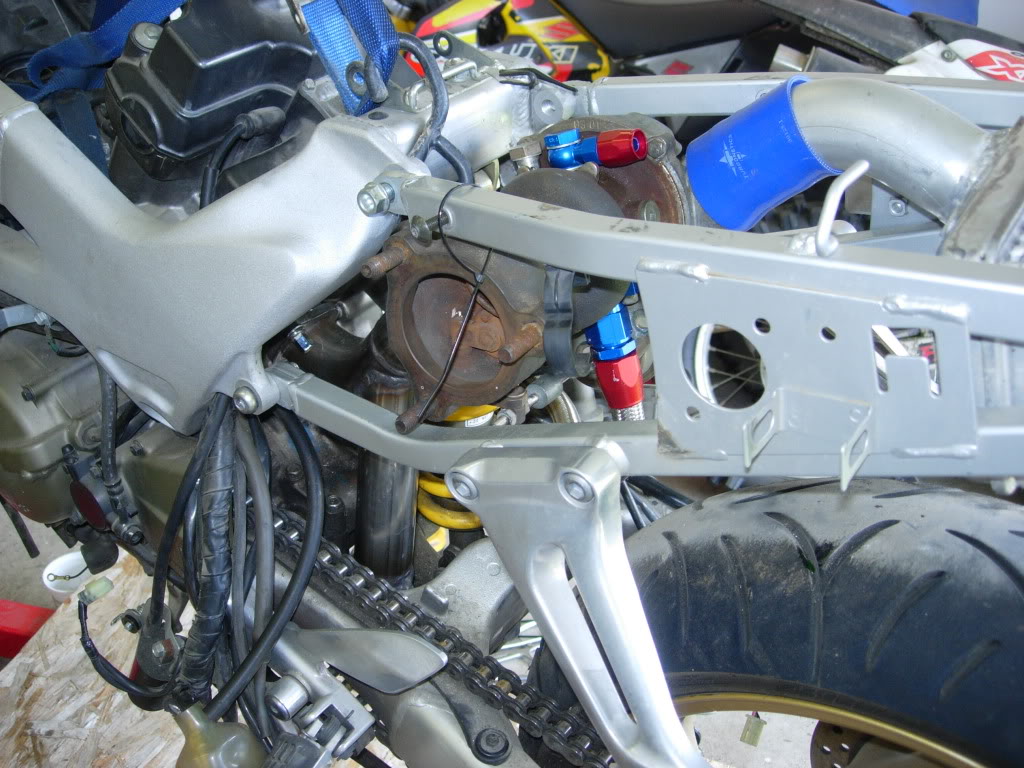

For the exhaust, I ordered some 1 3/4 304 Stainless bends, there was no way to get the flange so I cut it out of 1/4 Stainless sheet, I cut the stainless collector flanges from the stock exhaust and filed the 2 bolts clamps for the slightly bigger pipe, this is easy, but the final fitting is a major PITA, this thing is stiff, I made a tight slip joint at the swingarm height, with two hooks (not shown) for a spring.

Then it somehow looked like a turbo bike

Then I started the oil drainback, I had to remove the oil pan, clean, clean, clean, brush and clean to get all oil out, then I could weld my 10-AN bung, permatex, torque wrench and a good beer to cheer me up.

I will make heat shields for the seat, my left leg, the battery, there's a hell of a lot of details to take care of.

I should have started an oil thread instead

We ran out of work from that market crash, the fiber optics networks got paralyzed by the banks shutting down big projects. So for a while I had plenty of time, some money and the garage is almost done (I'll finish next winter

In the same time Quebec License dept, dropped the VTR to regular bikes and fee went from 1400 $ to around 5-600 $ and brought back some motivation.

Those who have modified a vehicle probably know that it always looks easier than it is, details are very time consuming and I want to do it right the first time, even if it's an open project, means that it have no end really and will change shape in the future.

My goal is a torque monster with no more horsepower than a CBR1000, but a full spool by 4000 RPM so the torque is not coming like getting rear ended by a racing granny.

It needs to be fun, it need to be build by me to my own specs, it need to be cheap and made using some junkyard parts, it need to looks as good as possible, but I'm a practical over bling type of person, I wash my bike twice a season.

I calculated mass flow, BSFC, VE and selected a Borg Warner K03 turbo for it's compressor map, price and availability, they are used on 1999 1.8 T Volks/Audi and support up to 180 hp worth of airflow.

I scored a 5,50$ intercooler on fleabay that I fitted to the rear of the bike, a custom unit could do better as a sleeper, but I don't mind the charge pipe that we see under the plastic.

Of course it will need to be fuel injected, I don't feel like blowing my motor, at least not before October for god's sake. At first I tried to use the carbs as throttle bodies, but I finally ditched the idea doing research on speed density on individual throttle bodies--->it sucks.

So I made an airbox that have the throttle before the plenum, I got a Datsun 240SX 60mm TB for a song.

I had the choice of buying parts for my bike or buying tools, I used what I had, but it took more brain matter, like my grinder/lathe to "machine" the bottom of the runners to fit the boots

This is the first version I made, the injector were too loose in it, so I bought for close to nothing a Malibu fuel rail and fuel pressure regulator that I chopped up in pieces, the last version is the last picture

For the exhaust, I ordered some 1 3/4 304 Stainless bends, there was no way to get the flange so I cut it out of 1/4 Stainless sheet, I cut the stainless collector flanges from the stock exhaust and filed the 2 bolts clamps for the slightly bigger pipe, this is easy, but the final fitting is a major PITA, this thing is stiff, I made a tight slip joint at the swingarm height, with two hooks (not shown) for a spring.

Then it somehow looked like a turbo bike

Then I started the oil drainback, I had to remove the oil pan, clean, clean, clean, brush and clean to get all oil out, then I could weld my 10-AN bung, permatex, torque wrench and a good beer to cheer me up.

I will make heat shields for the seat, my left leg, the battery, there's a hell of a lot of details to take care of.

Last edited by gboezio; 05-27-2009 at 04:31 PM.

#4

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

#8

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

Microsquirt is taking care or fuel and ignition, coupled with a Innovate LC-1 WB O2 sensor with the electronic gauge, injectors are 72 lb/h.

With heat shields it should be ok but while standing on the left leg, even trough a shield it may feel a bit hot, but not frying hot. I need to find that insulating material that sticks, or heat wrap the turbine housing. There is no way to fit a turbo on this thing without some sort of compromise, like setting my *** on fire for example

The only thing missing is time, work restarted like crazy.

When you have the cash you have no time, when you have the time you have no cash

With heat shields it should be ok but while standing on the left leg, even trough a shield it may feel a bit hot, but not frying hot. I need to find that insulating material that sticks, or heat wrap the turbine housing. There is no way to fit a turbo on this thing without some sort of compromise, like setting my *** on fire for example

The only thing missing is time, work restarted like crazy.

When you have the cash you have no time, when you have the time you have no cash

Last edited by gboezio; 05-26-2009 at 03:37 AM.

#16

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

Héhé thanks for the comments, I guess it's a need to customize our stuff, when the bike gets old by design we re-engineer stuff our way

Yeah by posting this on the forum, I'll owe a dyno sheet and a good vid of it on the track, specially with a sound clip, honestly I'm not sure what to expect for sound, not even sure what I will use as an exhaust, if I would try to figure out all the details my head will blow.

Progress will be made on the week ends, I'm working too much for now, I'm splicing, peeling cables all day long.

Nothing changed, but another pic just for the hell of it

Note the nice orange clock on the wall, this is a gift from my girlfriend, this way I come back for dinner before 4 am

Yeah by posting this on the forum, I'll owe a dyno sheet and a good vid of it on the track, specially with a sound clip, honestly I'm not sure what to expect for sound, not even sure what I will use as an exhaust, if I would try to figure out all the details my head will blow.

Progress will be made on the week ends, I'm working too much for now, I'm splicing, peeling cables all day long.

Nothing changed, but another pic just for the hell of it

Note the nice orange clock on the wall, this is a gift from my girlfriend, this way I come back for dinner before 4 am

Last edited by gboezio; 05-26-2009 at 08:13 PM.

#18

Wow, you are a madman (I mean that in the best possible way). Are you expecting this raptor to be streetable? It is very interesting that anyone would do this. Very John Britten (sp) or Eric Buell. I wish you the best. Keep us posted & PEACEOUT

#19

Uhhhhh BADASS.

I'm turbo ignorant when it comes to fuel mapping. How does the stock ECU fit into this picture? Or is it replaced entirely?

I love that you are going to sit on your turbo unit. So very mad max of you.

I'm turbo ignorant when it comes to fuel mapping. How does the stock ECU fit into this picture? Or is it replaced entirely?

I love that you are going to sit on your turbo unit. So very mad max of you.

#20

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

I'm running out of pics...and material to show lol

I'm a madman, my folder with bike picture is named bike insanity, strangely I'm not someone who likes to go very fast, I like tight low speed corners...followed by insane accelerations. I just had to do it and so far it cost a ridiculous amount of money, buy a hell of a lot of my time.

I will probably remove the ICU completely, Microsquirt should be able to read the 12-3 wheel trough the pulse gen, (VR), it support odd firing with two ignition channels, first at tach second tach + offset (270°here).

It has 12x12 ignition map, load x RPM, load is measured using speed density algorithm, there is a Manifold Absolute Pressure (MAP) sensor that measure the pressure of the plenum (throttle before plenum), the amount of air that the engine breathe is proportional to the pressure the throats "see"

TPS is used for accel enrich, coolant sensor, intake air temp for charge density.

Fuel is the same, 2x72 lb/h Seimens injectors, 3 Bar fuel pressure, inline fuel pump (will be loud), Microsquirt have a 12x12 fuel map, accel enrich (barely needed here, the injectors are aimed at the intake valves, low tau), cold enrich, fuel cut, idle control.

I may put a water valve as idle control at first until I can figure out my 3 wires PWM Bosch idle control valve, it need extra circuits to work.

The price of the Innovate LC-1 seem steep, but when you get the unit it goes wow...awesome quality and it's bigger that in looks, I may have to carry a trailer to put all those boxes of electronic gismos.

If someone else attempt this, I looked for small injectors that fits RC-51, SV-1000 throttle bodies, I have found some big enough, but after I ordered all my stuff, the problem is still the pulsing MAP signal, but it makes the intake simpler, but tuning a PITA.

I'm a madman, my folder with bike picture is named bike insanity, strangely I'm not someone who likes to go very fast, I like tight low speed corners...followed by insane accelerations. I just had to do it and so far it cost a ridiculous amount of money, buy a hell of a lot of my time.

I will probably remove the ICU completely, Microsquirt should be able to read the 12-3 wheel trough the pulse gen, (VR), it support odd firing with two ignition channels, first at tach second tach + offset (270°here).

It has 12x12 ignition map, load x RPM, load is measured using speed density algorithm, there is a Manifold Absolute Pressure (MAP) sensor that measure the pressure of the plenum (throttle before plenum), the amount of air that the engine breathe is proportional to the pressure the throats "see"

TPS is used for accel enrich, coolant sensor, intake air temp for charge density.

Fuel is the same, 2x72 lb/h Seimens injectors, 3 Bar fuel pressure, inline fuel pump (will be loud), Microsquirt have a 12x12 fuel map, accel enrich (barely needed here, the injectors are aimed at the intake valves, low tau), cold enrich, fuel cut, idle control.

I may put a water valve as idle control at first until I can figure out my 3 wires PWM Bosch idle control valve, it need extra circuits to work.

The price of the Innovate LC-1 seem steep, but when you get the unit it goes wow...awesome quality and it's bigger that in looks, I may have to carry a trailer to put all those boxes of electronic gismos.

If someone else attempt this, I looked for small injectors that fits RC-51, SV-1000 throttle bodies, I have found some big enough, but after I ordered all my stuff, the problem is still the pulsing MAP signal, but it makes the intake simpler, but tuning a PITA.

#21

You know with that exhaust routing and turbo there, not only is your legs going to be a bit toasty, but your poor shock is going to get heatstroke...  I'd consider a JD conversion with a remote res...

I'd consider a JD conversion with a remote res...

Also you sure you thought it through completely... I know it's not as important when running a turbo, but that's a biiig difference in exhaust gas speed with the difference of those headers...

Also you sure you thought it through completely... I know it's not as important when running a turbo, but that's a biiig difference in exhaust gas speed with the difference of those headers...

Last edited by Tweety; 05-27-2009 at 06:38 AM.

#22

I'm running out of pics...and material to show lol

I'm a madman, my folder with bike picture is named bike insanity, strangely I'm not someone who likes to go very fast, I like tight low speed corners...followed by insane accelerations. I just had to do it and so far it cost a ridiculous amount of money, buy a hell of a lot of my time.

I will probably remove the ICU completely, Microsquirt should be able to read the 12-3 wheel trough the pulse gen, (VR), it support odd firing with two ignition channels, first at tach second tach + offset (270°here).

It has 12x12 ignition map, load x RPM, load is measured using speed density algorithm, there is a Manifold Absolute Pressure (MAP) sensor that measure the pressure of the plenum (throttle before plenum), the amount of air that the engine breathe is proportional to the pressure the throats "see"

TPS is used for accel enrich, coolant sensor, intake air temp for charge density.

Fuel is the same, 2x72 lb/h Seimens injectors, 3 Bar fuel pressure, inline fuel pump (will be loud), Microsquirt have a 12x12 fuel map, accel enrich (barely needed here, the injectors are aimed at the intake valves, low tau), cold enrich, fuel cut, idle control.

I may put a water valve as idle control at first until I can figure out my 3 wires PWM Bosch idle control valve, it need extra circuits to work.

The price of the Innovate LC-1 seem steep, but when you get the unit it goes wow...awesome quality and it's bigger that in looks, I may have to carry a trailer to put all those boxes of electronic gismos.

If someone else attempt this, I looked for small injectors that fits RC-51, SV-1000 throttle bodies, I have found some big enough, but after I ordered all my stuff, the problem is still the pulsing MAP signal, but it makes the intake simpler, but tuning a PITA.

I'm a madman, my folder with bike picture is named bike insanity, strangely I'm not someone who likes to go very fast, I like tight low speed corners...followed by insane accelerations. I just had to do it and so far it cost a ridiculous amount of money, buy a hell of a lot of my time.

I will probably remove the ICU completely, Microsquirt should be able to read the 12-3 wheel trough the pulse gen, (VR), it support odd firing with two ignition channels, first at tach second tach + offset (270°here).

It has 12x12 ignition map, load x RPM, load is measured using speed density algorithm, there is a Manifold Absolute Pressure (MAP) sensor that measure the pressure of the plenum (throttle before plenum), the amount of air that the engine breathe is proportional to the pressure the throats "see"

TPS is used for accel enrich, coolant sensor, intake air temp for charge density.

Fuel is the same, 2x72 lb/h Seimens injectors, 3 Bar fuel pressure, inline fuel pump (will be loud), Microsquirt have a 12x12 fuel map, accel enrich (barely needed here, the injectors are aimed at the intake valves, low tau), cold enrich, fuel cut, idle control.

I may put a water valve as idle control at first until I can figure out my 3 wires PWM Bosch idle control valve, it need extra circuits to work.

The price of the Innovate LC-1 seem steep, but when you get the unit it goes wow...awesome quality and it's bigger that in looks, I may have to carry a trailer to put all those boxes of electronic gismos.

If someone else attempt this, I looked for small injectors that fits RC-51, SV-1000 throttle bodies, I have found some big enough, but after I ordered all my stuff, the problem is still the pulsing MAP signal, but it makes the intake simpler, but tuning a PITA.

#26

gboezio excellent idea, work and write-up.

I know you have probably seen this clip but here it is again to get the juices going, http://www.youtube.com/watch?v=vV0Hx...eature=related

I know you have probably seen this clip but here it is again to get the juices going, http://www.youtube.com/watch?v=vV0Hx...eature=related

#27

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

You know with that exhaust routing and turbo there, not only is your legs going to be a bit toasty, but your poor shock is going to get heatstroke...  I'd consider a JD conversion with a remote res...

I'd consider a JD conversion with a remote res...

Also you sure you thought it through completely... I know it's not as important when running a turbo, but that's a biiig difference in exhaust gas speed with the difference of those headers...

Also you sure you thought it through completely... I know it's not as important when running a turbo, but that's a biiig difference in exhaust gas speed with the difference of those headers...

The exhaust should work fine, the main flaws are the length of the front tube, but for a V-twin there is little choice, the second flaw is that the turbo would like the front better, but the weight unbalance was a too big trade off for me, the rear fire 270 ° after the front, the pulses will arrive to the collector even closer than this, if the rear was longer the pulses will we further from each other.

You get that Maudite beer in Ontario I think, Sleeman bought the company, they are just as rich as a bowl of cereal and 8 %, it may not be prophetic, but these hit like a hammer and building a bike drunk may cause the prophecy more than anything lol But I only drink a single beer during my work, then another when I'm done and contemplating.

Thanks, will post next week, I hope to have much work done this week end.

#28

I sat on my Hawk today with that in mind. It looks like the turbo exhaust output will be right where your leg will be when you come to a stop (foot on ground). Clearance wise, will the pipe need to come outside the frame before heading back to the muffler?

#29

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

I think it's on this forum that someone used a stuff that sticks, I want to cover the back of all my heat shields so they get barely warm.

The passenger pegs are gone already, the pipe angle will be about 45°down and rearward, then back to tail angle, 2 1/2 straight pipe at first

I will cheat the radius also, the 2 1/2 pipe is far from restrictive compared to the 1 3/4 discharge, I'm really considering modifying the tail frame to hug the bike even more

Last edited by gboezio; 05-28-2009 at 04:03 AM.

#30

Thread Starter

Senior Member

SuperSport

SuperSport

Joined: Dec 2006

Posts: 880

From: Victoriaville, Quebec, Canada

I worked on my bike this week end, I discovered a new ability, I can turn good aluminium into ****, I tried to cut the petcock to make a bung, this stuff is not weldable, well not with my equipment, I would need more electrode positive than what I have and probably a different filler, still I made the mother of all aluminium turd, so I had to seek another solution, I made a plate and sandwitched a O ring between the two surface and cracked a beer open.

Then to take my motivation to higher level, I made the charge pipe, there is so much cuts and welds in it, hammer dents to clear the damn head bolt, I made a good grinder job and brushed to fool the eye, still the inside is too boogery to my taste, we all know what a good flowing pipe is, but making one is sometime challenging due to space constrains.

But'still it's done, damn it, I just hope that the rest is less frustrating, splicing wires and tuning is more my thing than ripping knuckles like today.

3/8 NPT tap for IAT sensor on the airbox cover, so I don't get shavings when the airbox is closed.

Then to take my motivation to higher level, I made the charge pipe, there is so much cuts and welds in it, hammer dents to clear the damn head bolt, I made a good grinder job and brushed to fool the eye, still the inside is too boogery to my taste, we all know what a good flowing pipe is, but making one is sometime challenging due to space constrains.

But'still it's done, damn it, I just hope that the rest is less frustrating, splicing wires and tuning is more my thing than ripping knuckles like today.

3/8 NPT tap for IAT sensor on the airbox cover, so I don't get shavings when the airbox is closed.

That's really cool, but your *** is gonna be hot with that turbo sittin' right under it.

That's really cool, but your *** is gonna be hot with that turbo sittin' right under it.