Questions Regarding Swing-Arm Mods (929)

#1

Questions Regarding Swing-Arm Mods (929)

I know that there is a thread, somewhere on the Forum, in which one of the members shows a picture of his modified swing-arm, a modification that replaces the original F4-like, wimpy stock VTR swing-arm with a 929RR swing-arm. There is mention of the need to change the swing-arm bearings by measuring for bearing diameter, but I'm looking for more specifics on the process. (It is understandable that the exact details of the mod were not very dense in the post, as it wasn't a "how-to" post as much as it was a "hey, check-this-out-post.")

My questions specifically relate to the process of changing the rear swing-arm to one that is braced (or triangular like the 929RR and 954RR), without having to weld some sort of dealey onto the stock swing-arm.

I would really love to modify the swing-arm to be a 954RR swing-arm, but I don't know whether or not that is possible. (The mounting hardware and inside-diameter at the pivot point seem to be the key issues, since the swing-arm of the SuperChicken is technically mounted to the back of the engine, which is suspended from the frame, like the Ducati 916 engine; the pivot point mounting hardware also attaches to the foot pegs, the shift-lever assembly, and the rear brake lever assembly.)

First off, is it possible to modify to a 954RR swing-arm?

What swing-arms would be a possibility for a swing-arm modification that does not involve too much in the way of welding or grinding? (I don't want to get into situations where I modify too greatly the original design of the replacement swing-arm assembly; doing so might end-up being odd-ball engineering with unforeseen consequences.)

Lastly, what, specifically, are the steps involved in the modification that adds the 929RR swingarm, including bearing thickness and diameter?

Thanks for your help.

cheers,

--Professor Chaos

My questions specifically relate to the process of changing the rear swing-arm to one that is braced (or triangular like the 929RR and 954RR), without having to weld some sort of dealey onto the stock swing-arm.

I would really love to modify the swing-arm to be a 954RR swing-arm, but I don't know whether or not that is possible. (The mounting hardware and inside-diameter at the pivot point seem to be the key issues, since the swing-arm of the SuperChicken is technically mounted to the back of the engine, which is suspended from the frame, like the Ducati 916 engine; the pivot point mounting hardware also attaches to the foot pegs, the shift-lever assembly, and the rear brake lever assembly.)

First off, is it possible to modify to a 954RR swing-arm?

What swing-arms would be a possibility for a swing-arm modification that does not involve too much in the way of welding or grinding? (I don't want to get into situations where I modify too greatly the original design of the replacement swing-arm assembly; doing so might end-up being odd-ball engineering with unforeseen consequences.)

Lastly, what, specifically, are the steps involved in the modification that adds the 929RR swingarm, including bearing thickness and diameter?

Thanks for your help.

cheers,

--Professor Chaos

Last edited by ProfChaos; 08-18-2011 at 12:45 PM.

#2

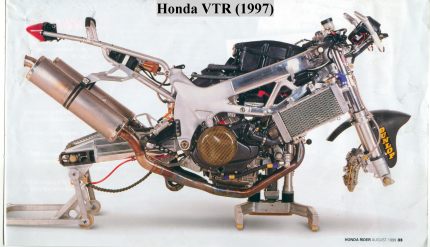

Well it's not a 954 arm that fits. What you would want is the swingarm off of an RC51 (SP2) and then you need to make your own shock linkage.

As for bracing the stock arm, I'm not sure why you think it is such a bad thing and there is no more fabrication time involved......

I guess the odd ball engineering does just look crappy......

As for bracing the stock arm, I'm not sure why you think it is such a bad thing and there is no more fabrication time involved......

I guess the odd ball engineering does just look crappy......

#3

Well it's not a 954 arm that fits. What you would want is the swingarm off of an RC51 (SP2) and then you need to make your own shock linkage.

As for bracing the stock arm, I'm not sure why you think it is such a bad thing and there is no more fabrication time involved......

I guess the odd ball engineering does just look crappy......Attachment 12328

Attachment 12329

Attachment 12330

As for bracing the stock arm, I'm not sure why you think it is such a bad thing and there is no more fabrication time involved......

I guess the odd ball engineering does just look crappy......Attachment 12328

Attachment 12329

Attachment 12330

I am working my way toward re-creating SuperChicken II (120 r.w.h.p., Ferrea light-weight valves; WebCam custom-grind, aggressive street cams; JE forged pistons; Dichronite coating on cam lobes, rings, and other friction-sensitive parts). I therefore need to come up with a swing-arm that will handle the extra torque and horsepower. What I meant by odd-ball engineering is that I've seen a few braces welded onto VTR swing-arms (over the years on e-Bay and at other Web sites) that did not seem to really be adding any structural support between the two legs of the swing-arm; they didn't seem to be doing much real re-enforcing, even if they did look quite cool.

I'm not concerned about initial looks so much, because I could always have the thing powder-coated silver--since I plan to do that with the wheels, anyway. (My current VTR [SuperChicken III] once belonged to a guy who abused it, did wheelies on it until the head bearing was shot, never cleaned the road dirt off of it, and left it out in the rain, so the clear-coating on the swing-arm is basically gone--etched-off by road-dirt toxins. The original swing-arm would thus have to be powder-coated if I used it in the mod, because SuperChicken III will be "the cat's pajamas" when I'm finished upgrading it.)

All that aside, since it re-enforces front-and-center and near the axle as well, your design looks like it would serve well in getting rid of that annoying twitch.

cheers,

--Professor Chaos

Last edited by ProfChaos; 08-18-2011 at 10:47 PM.

#4

CBR 929RR/954RR requires new bearings, and new headers combined with swapping the linkage since the CBR's have the shock on the other side... (or special lopsided linkage)

CBR 600RR/1000RR is a prolink swing, so those doesn't work at all... You'd end up welding/cutting in about 10 places

RC51 SP1 needs new bearings and a custom linkage, the SP2 needs custom linkage only, but is significantly longer than stock, affecting geometry and causing a lot of knock on effects, but I'm happy with it...

The least involved is to use the 900RR brace like hawk shows, or custom bent tubing...

CBR 600RR/1000RR is a prolink swing, so those doesn't work at all... You'd end up welding/cutting in about 10 places

RC51 SP1 needs new bearings and a custom linkage, the SP2 needs custom linkage only, but is significantly longer than stock, affecting geometry and causing a lot of knock on effects, but I'm happy with it...

The least involved is to use the 900RR brace like hawk shows, or custom bent tubing...

#5

If you want to tame your swing arm twist then you'll need frame brackets to help support the swing arm. Though this was only needed on track bikes putting out 140bhp...

http://www.speedzilla.com/forums/att...tage-2-003.jpg

...when Spondon modified those frames for the VTR Firestorm they strengthened that part of the frame casting and boxed that section in making it much stronger and rigid where the brackets were welded on.

http://www.speedzilla.com/forums/att...tage-2-003.jpg

#6

I notice the chassis flex on my bike every day - and it doesn't make much more hp than stock. It's not the engine output that demands better chassis rigidity, it's cornering loads. Once you start to push a VTR hard you quickly find out why Moriwaki put so much effort into strengthening the frame.

#7

If you want to tame your swing arm twist then you'll need frame brackets to help support the swing arm. Though this was only needed on track bikes putting out 140bhp...

http://www.speedzilla.com/forums/att...tage-2-003.jpg

http://www.speedzilla.com/forums/att...tage-2-003.jpg

where do i order a set of those? haha we all wish......back to the drawing board

#10

#11

So, I’m looking at this,, and you know..... the part itself, done from billet, is not overly complex. Somewhat large, and I’d have to be at home and spend some time to see just how large a billet would need to be pre machining. Once a CAD is made, the CNC machining is pretty simple.

Now finding a competent welder willing to graft that to the frame, then making a new swing arm pivot bolt, and the custom spacers needed, and the custom or modified swing arm,,, well that could be a road block..

#12

Sure they do when you consider the cost of the mods that some guys do to the VTR. You can buy a good RC51 or Aprilia Falco for within $1k of a similar shape VTR all day long. You close that gap just doing the suspension on the VTR and the RC still makes more power and has a better handling chassis, both of which are performance gaps that you can never close with a Superhawk.

#13

I notice the chassis flex on my bike every day - and it doesn't make much more hp than stock. It's not the engine output that demands better chassis rigidity, it's cornering loads. Once you start to push a VTR hard you quickly find out why Moriwaki put so much effort into strengthening the frame.

So to deal with this, I just accept the Hawk for what it is and don't ride it that hard. Problem solved.

Thread

Thread Starter

Forum

Replies

Last Post

marmaladedad

Technical Discussion

2

01-15-2005 11:04 AM