RC51 (SP2) rear end swap

#1

RC51 (SP2) rear end swap

I had been hi-jacking stebbdt's thread asking questions so I thought I would start my own.

Started designing a linkage to "plug n' play" the swing arm in to the stock shock and engine tie bar.

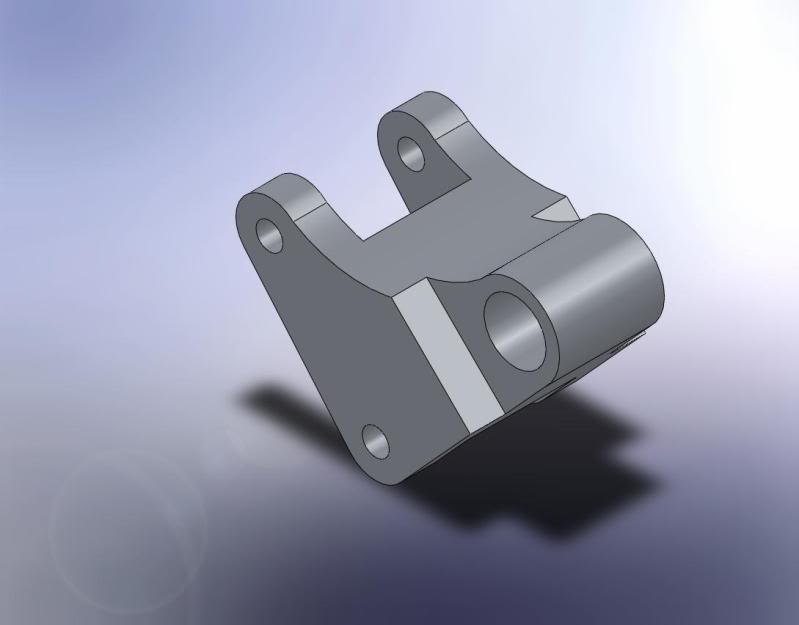

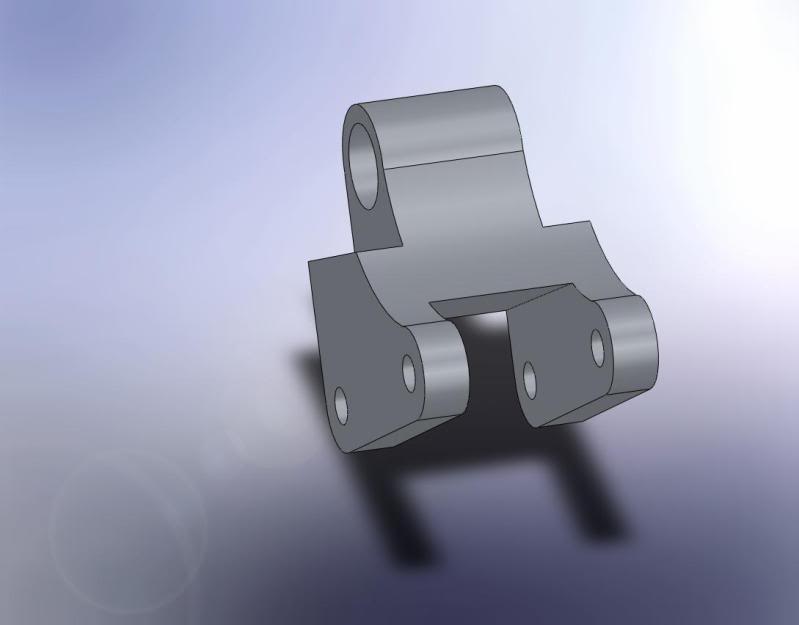

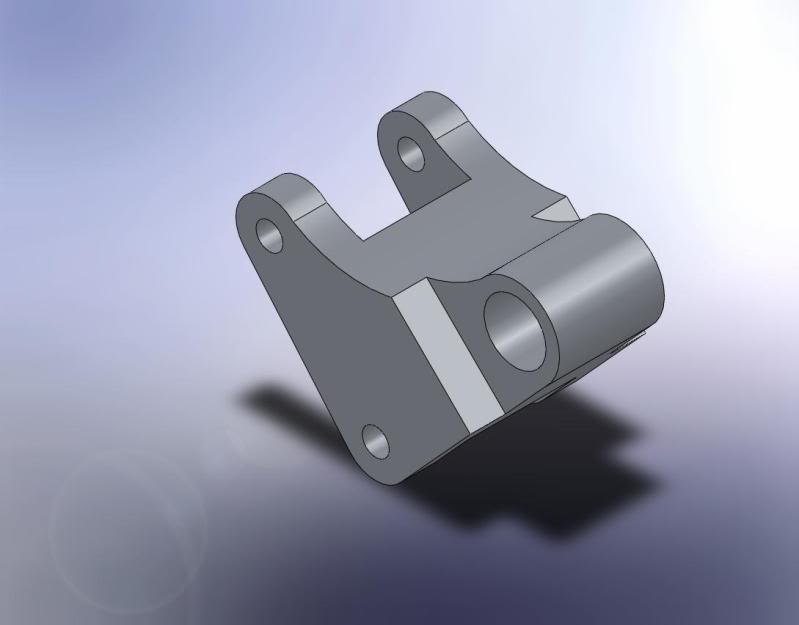

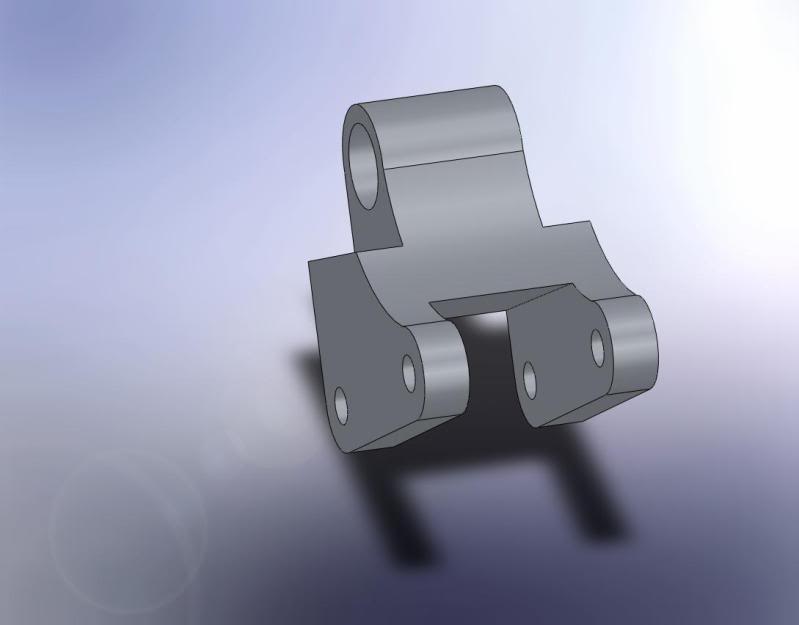

Looked like this in solidworks

Finaly picked it up today, buts its going back tomorrow to get anodised black with some RSV4 rear sets the machineist is doing, took it home today to make sure its fits ok in to the swing arm

This is how it measures up against the SP linkage

Started designing a linkage to "plug n' play" the swing arm in to the stock shock and engine tie bar.

Looked like this in solidworks

Finaly picked it up today, buts its going back tomorrow to get anodised black with some RSV4 rear sets the machineist is doing, took it home today to make sure its fits ok in to the swing arm

This is how it measures up against the SP linkage

Last edited by Gaggenau; 08-12-2010 at 04:49 AM.

#2

This is the fitting in to the swing arm, it looks tight but its moves freely

Here is the weight of the new part (no bearings) compared to the SP linkage (bearings fitted)

Here are some of the other bits i have, Swing arm, SP1 6 spoke wheel,, caliper and NWS carbon hugger

Just got to get a speocket carrier and spacer, and bearings for the new linkage, will be using stock honda ones from the SP linkage

Here is the weight of the new part (no bearings) compared to the SP linkage (bearings fitted)

Here are some of the other bits i have, Swing arm, SP1 6 spoke wheel,, caliper and NWS carbon hugger

Just got to get a speocket carrier and spacer, and bearings for the new linkage, will be using stock honda ones from the SP linkage

Last edited by Gaggenau; 08-12-2010 at 04:42 AM.

#5

And my friend was talking about wanting to do an RC51 swingarm swap yesterday...

________

DAIHATSU ESSE SPECIFICATIONS

________

DAIHATSU ESSE SPECIFICATIONS

Last edited by Firefly; 02-27-2011 at 05:51 PM.

#6

Ordered bearings, seals, cush rubbers, chain slider, spacers and various bolts from the local honda stealership so they should be here soon and now just waiting on a best offer reply on a sprocket carrier.

#9

Untill have put a few miles on it and havent killed my self in the process, im not gona give any of the designs out, i dont want to feel in any way responsible if anything should go wrong, at least if im the only one who has it, then im possibley the only one who could get hurt.

The hole dimensions you are more than welcome to, tweety gave me them originaly, i can put them up here again if you want to make a start and have a go?

I hope im not comming accross like an ****, i just dont want to get anyone hurt.

Picked up all the bits from the local stealership yesterday, appart from two collars that sit in the swing arm pivot and the sprocket carrier was delivered to work too.

Had a shitty tyre put on the rim to make sure it keeps pressure as it had a little flat in the rim, its been a week now and its still dead on what was put in it, so im gona knock the bearings out and get it powder coated black

The hole dimensions you are more than welcome to, tweety gave me them originaly, i can put them up here again if you want to make a start and have a go?

I hope im not comming accross like an ****, i just dont want to get anyone hurt.

Picked up all the bits from the local stealership yesterday, appart from two collars that sit in the swing arm pivot and the sprocket carrier was delivered to work too.

Had a shitty tyre put on the rim to make sure it keeps pressure as it had a little flat in the rim, its been a week now and its still dead on what was put in it, so im gona knock the bearings out and get it powder coated black

#11

Some more pics, sorry about the quality, the BB curve hasnt the best camera in the world!

Fitted the delivered sprocked carrier and the rest of the gubbins realy to make sure that the SP1 wheel, sprocket carrier and spacers fitted into the SP2 arm and the do

I left off the disc and caliper, much easier to pit it this way without having to line up the calipers over the disc.

Fitted the delivered sprocked carrier and the rest of the gubbins realy to make sure that the SP1 wheel, sprocket carrier and spacers fitted into the SP2 arm and the do

I left off the disc and caliper, much easier to pit it this way without having to line up the calipers over the disc.

#12

Untill have put a few miles on it and havent killed my self in the process, im not gona give any of the designs out, i dont want to feel in any way responsible if anything should go wrong, at least if im the only one who has it, then im possibley the only one who could get hurt.

The hole dimensions you are more than welcome to, tweety gave me them originaly, i can put them up here again if you want to make a start and have a go?

I hope im not comming accross like an ****, i just dont want to get anyone hurt.

Picked up all the bits from the local stealership yesterday, appart from two collars that sit in the swing arm pivot and the sprocket carrier was delivered to work too.

Had a shitty tyre put on the rim to make sure it keeps pressure as it had a little flat in the rim, its been a week now and its still dead on what was put in it, so im gona knock the bearings out and get it powder coated black

The hole dimensions you are more than welcome to, tweety gave me them originaly, i can put them up here again if you want to make a start and have a go?

I hope im not comming accross like an ****, i just dont want to get anyone hurt.

Picked up all the bits from the local stealership yesterday, appart from two collars that sit in the swing arm pivot and the sprocket carrier was delivered to work too.

Had a shitty tyre put on the rim to make sure it keeps pressure as it had a little flat in the rim, its been a week now and its still dead on what was put in it, so im gona knock the bearings out and get it powder coated black

But it should be noted that the dimensions are not going to work very well with a stock VTR shock or an aftermarked shock with stock length... For one, the rear will point very high in the sky... And two, the linkage needs a slightly softer shock setting than stock to work optimally...

You need either an aftermarket shock with adjustable length or like me a rebuilt F4i shock with an adjustable clevis mount... I'll gladly provide all basic information needed to build that...

But like the information I gave Gaggenau, I give the basic measurements and an idea... The final shape and form is up to you to figure out... If you have the know-how it's "easy"... If you haven't got a clue, well... Then you are likely to hurt yourself if you get to much help building it... That's how I look at things...

Last edited by Tweety; 08-18-2010 at 02:29 PM.

#13

This is the adjustable top clevis I made to hold a stock lenght F4i shock...

The threaded bar is M14, and I recommend Nyloc nuts, this was a test mounting with standard ones... You will need to drill the hole in the frame larger as it's an M10 bolt on the stock clevis... And remember to use high tensile steel, not a unknown/unmarked piece...

The threaded bar is M14, and I recommend Nyloc nuts, this was a test mounting with standard ones... You will need to drill the hole in the frame larger as it's an M10 bolt on the stock clevis... And remember to use high tensile steel, not a unknown/unmarked piece...

#14

Yes, I agree if I was asked to make any then they would be at cost, I wouldnt want to make high proffit out of them at all, as thats not what I am in to and since I didnt do all the design my self, it would be unfair.

Like i said at the moment im not going be releasing any thing about it, only for my peace of mind and your safety.

And i totaly agree with tweety's statement

"But like the information I gave Gaggenau, I give the basic measurements and an idea... The final shape and form is up to you to figure out... If you have the know-how it's "easy"... If you haven't got a clue, well... Then you are likely to hurt yourself if you get to much help building it... That's how I look at things..."

Like i said at the moment im not going be releasing any thing about it, only for my peace of mind and your safety.

And i totaly agree with tweety's statement

"But like the information I gave Gaggenau, I give the basic measurements and an idea... The final shape and form is up to you to figure out... If you have the know-how it's "easy"... If you haven't got a clue, well... Then you are likely to hurt yourself if you get to much help building it... That's how I look at things..."

#15

I can understand your concerns in our litigious society. If you have dimensions you can can share that would be great. I do not have the required parts to take measurements from but would love to at least get started with the design process and be that much closer when I do find them.

Tweety since you did the mathematics legwork for us, can you elaborate on the changes to the linkage ratio and how spring rate is affected with the changes?

It's great to be able to stand on the shoulders of giants once in a while. Thanks Tweety, Gaggenau, and everyone else who has posted their developments here for the benefit of the community.

Tweety since you did the mathematics legwork for us, can you elaborate on the changes to the linkage ratio and how spring rate is affected with the changes?

It's great to be able to stand on the shoulders of giants once in a while. Thanks Tweety, Gaggenau, and everyone else who has posted their developments here for the benefit of the community.

#16

I can understand your concerns in our litigious society. If you have dimensions you can can share that would be great. I do not have the required parts to take measurements from but would love to at least get started with the design process and be that much closer when I do find them.

Tweety since you did the mathematics legwork for us, can you elaborate on the changes to the linkage ratio and how spring rate is affected with the changes?

It's great to be able to stand on the shoulders of giants once in a while. Thanks Tweety, Gaggenau, and everyone else who has posted their developments here for the benefit of the community.

Tweety since you did the mathematics legwork for us, can you elaborate on the changes to the linkage ratio and how spring rate is affected with the changes?

It's great to be able to stand on the shoulders of giants once in a while. Thanks Tweety, Gaggenau, and everyone else who has posted their developments here for the benefit of the community.

Uhm... You sure about the elaborate part? I'm an engineer remember... I have a couple of notebook pages of math if you want it...

The short version... The swingarm is 45 mm longer than the stock, making the wheelbase 38mm longer with that linkage (this is all from memory, so could be off a few mm, but close enough) and effectively raising the rear 10-15mm... Since the leverage is longer, the spring should be a bit lighter, or less preloaded... My shock was built to spec for me by Jamie Daugherty, so I'm currently running running it on the lower end of the preload, which is working fine...

The shock needs to be roughly 10-15 mm shorter than the OEM one for the same basic geometry (aside from longer wheelbase)... Mine is currently setup where it's only a few mm's shorter, giving me a very tall rear, same as a very thick shim on the stock shock would... I'm 6'4" so I like it that way...

I ran the F4i shock on my bike a while before the swap, and I have backed of the spring preload 3 (4?) notches as it is now, and that feels basicly right on both setups (Keep in mind that that test was a short time...)

#17

Found it! Anyone care to share their measurements form an SP2 swing arm or stock suspension linkage? I wish Honda would publish this stuff.

Tweety if you still have your calcs and they are in an easy to transmit format I'd like to see them. Otherwise, no problem I'll figure it out.

Tweety if you still have your calcs and they are in an easy to transmit format I'd like to see them. Otherwise, no problem I'll figure it out.

#18

The peice that slots in to the SP2 swing arm needs to be 38mm thick, the hole the bearing sits in(if you use honda bearings from the SP2/1 linkage) needs to be 24mm Dia

The distance the firestorm shock and engine tie bar sit in is 39mm IIRC

The other two holes need to be 10mm Dia

The distance the firestorm shock and engine tie bar sit in is 39mm IIRC

The other two holes need to be 10mm Dia

Last edited by Gaggenau; 08-19-2010 at 10:26 AM.

#19

Well, I can gladly say that this does not interest me for this winter, at least not yet. New fairings and a paint job are in order. What color? That's for another thread and pictures when it's done.

#20

I'm working on the same project.....RC51 SP2 swingarm mod at the moment. I would really love to hear how it all ended up working for you. I am waiting for my swingarm to show up in the next day or two, and then I will be undergoing the task of designing and building the linkage. If yours ended up working well I would sure appreciate any helpful tips. I have already seen your awsome pictures of your link design, and have got the measurements from tweety's design.

Thanks, Walt

Thanks, Walt

#21

+ 1 trying to decide if I should go with a braced arm or the sp2.

I have everything I need for the braced arm but a tig welder.

What do you guys think are the advantages or disadvantages to each swing arm.

I have everything I need for the braced arm but a tig welder.

What do you guys think are the advantages or disadvantages to each swing arm.

#22

Stumpy from what I have come to understand the advantage to the rc51 sp2 swingarm is that there should be no welding required depending on how you solve the linkage issue. Also and probably formost is that you can use the 1000rr rear wheel which is wider than stock and I believe a bit lighter as well. I am exploring this route in order to be able to use the matching front and rear cbr1000rr wheels. Looks are another consideration as well. The Sp2 swingarm looks really trick.

Im no expert yet but I hope I helped or enticed a more knowledgable SH guru to respond.

Cheers, Walt

Im no expert yet but I hope I helped or enticed a more knowledgable SH guru to respond.

Cheers, Walt

#23

Well, yeah you don't need to weld... pro or con can be discussed...

The SP2 swingarm adds lenght to the wheelbase (and as a way of compensating some of that lenght, height) which is also a a debatable pro/con result... Longer wheelbase means more stable bike, and longer swing means more weight bias on the front wheel... It also means slower steering unless you add height in the rear which is easy with a long swing...

It reduces weight... The SP2 swing is little over half the weight of the stock one despite it's deceptive chunky looks...

And to even consider it you need a height adjustable shock... Preferrably one that can be made shorter than stock lenght... That adds cost... Do NOT try this with the stock shock, you will end up in a ditch...

With it comes the option to run either the CBR 600RR 5.5" wheel or the CBR 1000RR 6" wheel... Both are lighter than stock by far... Running the wider 6" rim is mostly negative for handling... It will make the bike more lazy... But you get ridiculous amounts of rubber to lean the bike over on if you dare too... I'm still working on my chickenstrips...

An option is to use the SP1 swing instead... Needs new bearings for the pivot, but otherwise fits just the same... It's a bit heavier and shorter... Still longer and lighter than the stock one though, and still the same choice in wheels...

The SP2 swingarm adds lenght to the wheelbase (and as a way of compensating some of that lenght, height) which is also a a debatable pro/con result... Longer wheelbase means more stable bike, and longer swing means more weight bias on the front wheel... It also means slower steering unless you add height in the rear which is easy with a long swing...

It reduces weight... The SP2 swing is little over half the weight of the stock one despite it's deceptive chunky looks...

And to even consider it you need a height adjustable shock... Preferrably one that can be made shorter than stock lenght... That adds cost... Do NOT try this with the stock shock, you will end up in a ditch...

With it comes the option to run either the CBR 600RR 5.5" wheel or the CBR 1000RR 6" wheel... Both are lighter than stock by far... Running the wider 6" rim is mostly negative for handling... It will make the bike more lazy... But you get ridiculous amounts of rubber to lean the bike over on if you dare too... I'm still working on my chickenstrips...

An option is to use the SP1 swing instead... Needs new bearings for the pivot, but otherwise fits just the same... It's a bit heavier and shorter... Still longer and lighter than the stock one though, and still the same choice in wheels...

#24

Tweety I am all ears when you speak. I Just didnt understand however that you would need a shorter shock and not to try it with a stock shock. I am hoping to try it with a VTR 1000f Specced Ohlins shock. If the link is custom made as I am led to believe it will be, won't the length from link to shock be up to whoever custom makes the link? Please let me know if I am misunderstanding, because I am about at that stage. Of the threads I have read through, I never found the end all blueprints. If I missed that thread please link it.

Thanks, Walt

Thanks, Walt

Last edited by trident00; 11-04-2010 at 06:24 PM.

#25

Well, the main reason for not using a stock shock is that it's utter crap and could just as nicely be replaced by a nice pine 2x4... It wouldn't really make the suspension characteristics much worse...

Other than that, the information is in several places... One is post #16 in this thread, just scroll up and read...

The reason for why you never found an "end all blueprint" can be read in post #12 & #14... I still stand by it, sorry...

You can certainly do it with the stock lenght shock... And yes, a custom piece like that in the pics above can probably be adapted to use a longer shock, but changing one part means changing the others as well... Ie throw all the dimensions out and start from scratch...

A longer shock means a lot higher rear end if you keep the other dimensions the same... If you start changing the height by changing the triangle's dimensions, you also change the leverage and that means you change how the shock works... Ie you might not like how the ride ends up... Lots of math to get that right... I did the math one that case, you want another geometry you get to do it all over on your own...

Other than that, the information is in several places... One is post #16 in this thread, just scroll up and read...

The reason for why you never found an "end all blueprint" can be read in post #12 & #14... I still stand by it, sorry...

You can certainly do it with the stock lenght shock... And yes, a custom piece like that in the pics above can probably be adapted to use a longer shock, but changing one part means changing the others as well... Ie throw all the dimensions out and start from scratch...

A longer shock means a lot higher rear end if you keep the other dimensions the same... If you start changing the height by changing the triangle's dimensions, you also change the leverage and that means you change how the shock works... Ie you might not like how the ride ends up... Lots of math to get that right... I did the math one that case, you want another geometry you get to do it all over on your own...

Last edited by Tweety; 11-04-2010 at 07:39 PM.

#26

If I read correctly through all of this, it was designed with the stock shock in mind. As far as the difference in ride height and the adapter triangle, I understand all of that completely. I dont have a spare rc51 to compare to so I cant take the measurements myself tonight. I do however understand the mechanical relationships and that there are aftermarket rc51 linkages designed to adjust the geometry from progressive to a more controllable linear. I do know from your drawings and the corrected angular measurements, that two of the points are taken exactly from the stock linkage. The variable in that case is the distance and angles from the stock linkage to the swingarm attachment point. I also have been toying with a design that would set the linkage point for the engine mount and the swingarm and provide an adjustable linkage between the (triangular)linkage and the shock. The stresses at that point should all be fairly linear and adjustment would be handled controlbly at the modified linkage area instead of being handled at the frame. I do understand that this is truly hard to describe without pictures. I know from reading all this that many of the user attempted mods apprear to still be all up in the air as of yet. The only working mod I know of for sure with any documentation is yours tweety which was done with rewelding the attachment pont to the swingarm.

I am hoping to try and tie all the other attempts together with some new insight into something we can all benifit from. I'm certainly not out to make a career of this and if it becomes that much of a PITA for me I will just punt and pour the funds and time elsewhere. As far as looking back to the threads where peops covered their tail about their designs, I can respect that to a point. I will share my info freely with the knowledge that I do not endorse any of it and it is all untested research and development. I would be happy to share my notes with anyone.

I am hoping to try and tie all the other attempts together with some new insight into something we can all benifit from. I'm certainly not out to make a career of this and if it becomes that much of a PITA for me I will just punt and pour the funds and time elsewhere. As far as looking back to the threads where peops covered their tail about their designs, I can respect that to a point. I will share my info freely with the knowledge that I do not endorse any of it and it is all untested research and development. I would be happy to share my notes with anyone.

Last edited by trident00; 11-04-2010 at 08:19 PM.

#27

Well see I have a olines shock that I droped $1000 on a few years back but I really want to use the sp2 so im hoping that someone will get this worked out. I would be interested it trading the unfinished braced swingarm for help with this I have all parts needed and ruff cut. just needs to be welded up. and some sort of fender and chain gard as I dont think my huger will fit it . I see other benifits as well like the better chain adjustments, more options for rearsets not that mine dont work good droped a few bucks on them as well and when I worked in a machine shop I put bearings in place of the bushings. but eather way i need to get this done as my new engine should be ready in the sping.

#28

Well see I have a olines shock that I droped $1000 on a few years back but I really want to use the sp2 so im hoping that someone will get this worked out. I would be interested it trading the unfinished braced swingarm for help with this I have all parts needed and ruff cut. just needs to be welded up. and some sort of fender and chain gard as I dont think my huger will fit it . I see other benifits as well like the better chain adjustments, more options for rearsets not that mine dont work good droped a few bucks on them as well and when I worked in a machine shop I put bearings in place of the bushings. but eather way i need to get this done as my new engine should be ready in the sping.

#29

If I read correctly through all of this, it was designed with the stock shock in mind. As far as the difference in ride height and the adapter triangle, I understand all of that completely. I dont have a spare rc51 to compare to so I cant take the measurements myself tonight. I do however understand the mechanical relationships and that there are aftermarket rc51 linkages designed to adjust the geometry from progressive to a more controllable linear. I do know from your drawings and the corrected angular measurements, that two of the points are taken exactly from the stock linkage. The variable in that case is the distance and angles from the stock linkage to the swingarm attachment point. I also have been toying with a design that would set the linkage point for the engine mount and the swingarm and provide an adjustable linkage between the (triangular)linkage and the shock. The stresses at that point should all be fairly linear and adjustment would be handled controlbly at the modified linkage area instead of being handled at the frame. I do understand that this is truly hard to describe without pictures. I know from reading all this that many of the user attempted mods apprear to still be all up in the air as of yet. The only working mod I know of for sure with any documentation is yours tweety which was done with rewelding the attachment pont to the swingarm.

I am hoping to try and tie all the other attempts together with some new insight into something we can all benifit from. I'm certainly not out to make a career of this and if it becomes that much of a PITA for me I will just punt and pour the funds and time elsewhere. As far as looking back to the threads where peops covered their tail about their designs, I can respect that to a point. I will share my info freely with the knowledge that I do not endorse any of it and it is all untested research and development. I would be happy to share my notes with anyone.

I am hoping to try and tie all the other attempts together with some new insight into something we can all benifit from. I'm certainly not out to make a career of this and if it becomes that much of a PITA for me I will just punt and pour the funds and time elsewhere. As far as looking back to the threads where peops covered their tail about their designs, I can respect that to a point. I will share my info freely with the knowledge that I do not endorse any of it and it is all untested research and development. I would be happy to share my notes with anyone.

Well, my build is well documented, hawkster996 that started me on this path has never shared his dimensions on the triangle so what his geometrics with a stock shock is untested/undocumented...

The reason the two measurements on the triangle are the same as stock is easy... They directly correspond to the engine mount and the line where the shock is loaded along it's length and not at an angle... Also using the RC51 lingage as template is a dead end as that uses a completely different design, with a much, much softer shock...

Another thing to take into account is the fact that when you change the triangle beyond certain boundaries it starts tilting around one point exclusively, which once again changes all the math... You don't want that...

I'd be very interested to see a sketch of your idea for an adjustable link, space is most definetly at a premium in there...

Also as for me sharing or not sharing... I share 99% of a working solution and expect people to figure out the last part... That means when you change things you get to do research for that, not me...

BTW I was sorely tempted to reply to your post with "go search"... The reasons for that being simple... You have gotten that reply in a few other threads when you asked things already spelled out, and answered "I have searched, I have read, I didn't find an answer!"

This time you had the information available in three threads, one of them a few posts above where you asked... That makes it pretty clear you haven't spent that much time reading...

Now, if you want to throw a tantrum over this comment, fine by me, but remember two things... One, I didn't... Two, it doesn't really help either of us... Three, at one point or another, the smart move is to admit the other guy might have a point and let it be even if you don't agree 100%...

I'm looking forward to more of this discussion, since you are asking questions in a manner that tells me you understand what we are talking about...

#30

Sheesh, would it kill you to use paragraphs? I'm trying to read on an iPhone screen...

BTW I was sorely tempted to reply to your post with "go search"... The reasons for that being simple... You have gotten that reply in a few other threads when you asked things already spelled out, and answered "I have searched, I have read, I didn't find an answer!"

This time you had the information available in three threads, one of them a few posts above where you asked... That makes it pretty clear you haven't spent that much time reading...

Now, if you want to throw a tantrum over this comment, fine by me, but remember two things... One, I didn't... Two, it doesn't really help either of us... Three, at one point or another, the smart move is to admit the other guy might have a point and let it be even if you don't agree 100%...

I'm looking forward to more of this discussion, since you are asking questions in a manner that tells me you understand what we are talking about...

BTW I was sorely tempted to reply to your post with "go search"... The reasons for that being simple... You have gotten that reply in a few other threads when you asked things already spelled out, and answered "I have searched, I have read, I didn't find an answer!"

This time you had the information available in three threads, one of them a few posts above where you asked... That makes it pretty clear you haven't spent that much time reading...

Now, if you want to throw a tantrum over this comment, fine by me, but remember two things... One, I didn't... Two, it doesn't really help either of us... Three, at one point or another, the smart move is to admit the other guy might have a point and let it be even if you don't agree 100%...

I'm looking forward to more of this discussion, since you are asking questions in a manner that tells me you understand what we are talking about...

On your i phone......... you must of thought you were gettin into "War and Peace", or the freakin Bible. By the way, what'd you have for breakfast this morning. I wanna get some of it. haha

my two questions are: does it matter which two he remembers? and Did you

add a third because the name, "trident", suggests he may be able to deal with threes more effectively? and Three, what did you have for breakfast this morning?