fairing repair

#1

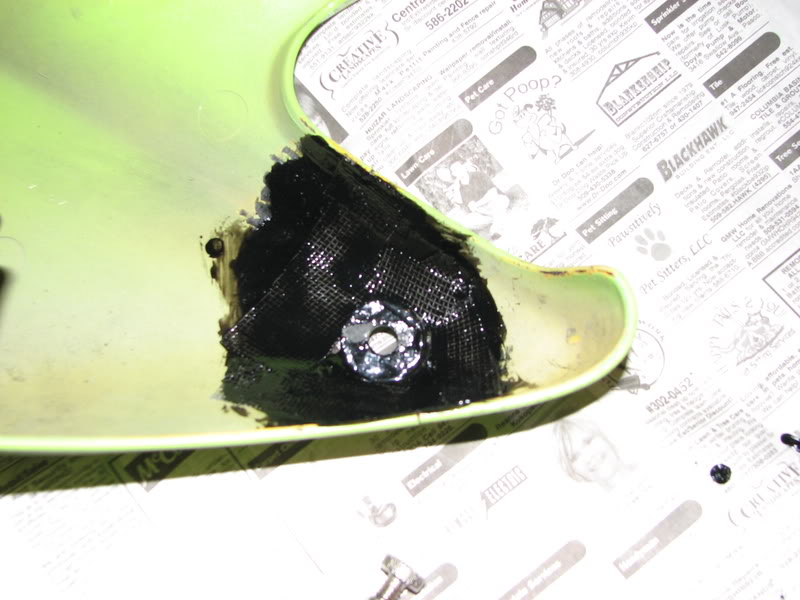

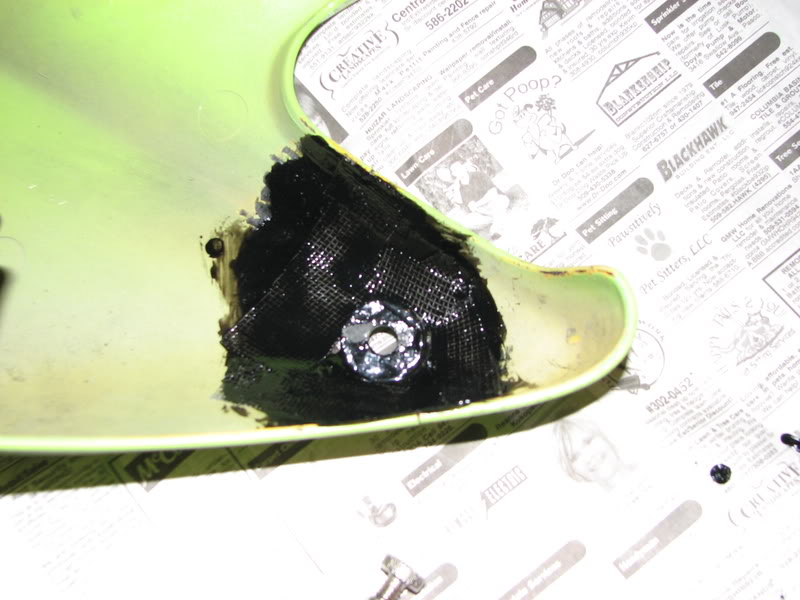

fairing repair (ALL DONE!).. pretty much

pretty much done, i just have to clean up the outside a bit. here are the pictures.

i used abs cement with fiberglass window screen repair patches. it worked really great.

i used a dremel to rough up the plastic before using the cement.

clamped the pieces together

threw on the first coat of cement and then added a layer of fiberglass

then i put another layer of cement over the fiberglass and that's that

this is what it now looks like

i know it doesnt look beautiful, but i acheived exactly what i wanted too, so im satisfied.

i used abs cement with fiberglass window screen repair patches. it worked really great.

i used a dremel to rough up the plastic before using the cement.

clamped the pieces together

threw on the first coat of cement and then added a layer of fiberglass

then i put another layer of cement over the fiberglass and that's that

this is what it now looks like

i know it doesnt look beautiful, but i acheived exactly what i wanted too, so im satisfied.

Last edited by Death Cattle; 02-09-2009 at 06:50 PM.

#3

DC, that's a real shame bro! If you're willing to go to the trouble you could fiberglass it back together. I've never tried it, but figure it would work if you refinished it afterwards with body putty and repainted, but I'd recommend saving yourself the grief and buy a used piece of plastic and just use it as an excuse to paint it Red=fastest color

RC

RC

#4

I have one of of the USC plastic "welders"... it works well, but a cheap soldering iron and a few of the ABS repair rods would probably be just as effective to fis that... you'll need sand and paint regardless...

J.

J.

#5

Get it plastic welded if you can get it done over the pond. I have heard of it done DIY with plastic coat hangers (as a 'solder' and a soldering iron) - need to make the fractured parts into a grooved v-angle for the plastic 'solder' to flow into.

Link http://kr250.org/KR_service.htm#panels

Alternatively, rough up the back of the fairing to expose a key surface on the plastic - use some epoxy resin, fine aluminium mesh / fibre glass to join up and reinforce the back of the panel. Not pretty or perfect but will hold it together - More prep work, sanding & filling (flexible bumper filler), priming and finishing needed to get it acceptable to the eye. (Resprayers who need to bake the paint won't touch glass-fibre repaired panels)

I fixed together my panel that got wrecked when the indicator punched through - drilled the cracks so they wouldn't spread. Masked up the front surface (so resin wouldn't ooze out) and did the repairs behind as described. Didn't bother to finish the outside and keep a brand new replacement fairing panel I got in compensation in reserve for a rainy day.

Link http://kr250.org/KR_service.htm#panels

Alternatively, rough up the back of the fairing to expose a key surface on the plastic - use some epoxy resin, fine aluminium mesh / fibre glass to join up and reinforce the back of the panel. Not pretty or perfect but will hold it together - More prep work, sanding & filling (flexible bumper filler), priming and finishing needed to get it acceptable to the eye. (Resprayers who need to bake the paint won't touch glass-fibre repaired panels)

I fixed together my panel that got wrecked when the indicator punched through - drilled the cracks so they wouldn't spread. Masked up the front surface (so resin wouldn't ooze out) and did the repairs behind as described. Didn't bother to finish the outside and keep a brand new replacement fairing panel I got in compensation in reserve for a rainy day.

Last edited by Wicky; 01-07-2009 at 12:21 PM.

#7

I had a few cracked areas around holes that I sanded the inside of and fiberglassed them. Then I just dremeled the leftover resin anywhere that clearance was an issue. It was a kit from the autoparts store, made by Bondo. (But not WITH bondo!)

Was nothing like what you posted, but I don't see why that wouldn't work also. Better than spending $400 plus paint for a replacement.

Was nothing like what you posted, but I don't see why that wouldn't work also. Better than spending $400 plus paint for a replacement.

Last edited by CentralCoaster; 01-07-2009 at 02:43 PM.

#8

What ever you do. Dont use these guys.www.empiregp.com You will not be happy with their work.

Last edited by jmyg79; 01-07-2009 at 06:46 PM.

#9

What ever you do. Dont use these guys.www.empiregp.com You will not be happy with their work.

thanks

#12

Fiberglass will not bond to the ABS plastic that well, and I've never had great success with the plastic welder kits. Just get some ABS cement from ACE Hardware, it's in the plumbing section. I do a lot of ABS bodywork repairs in my buisness... trust me, this stuff works. Only use it on the back side of the plastic. If you put it on the outside, when you paint over it the paint will have a chemical reaction and "spider". Before you apply it, rough up the area with some 220 grit sandpaper. Put down a couple coats letting it dry between applications and you are good to go!

#13

well i have a fucked up left cowling.....I think that section of the cowl is still good....so maybe you could cut off that section and the other equally, then swap. then only have one controlled line to weld...instead of a bunch of fragments... I'll look and see when I get a chance. that part it in a friends garage right now. does this make sense to everyone?

#14

Fiberglass will not bond to the ABS plastic that well, and I've never had great success with the plastic welder kits. Just get some ABS cement from ACE Hardware, it's in the plumbing section. I do a lot of ABS bodywork repairs in my buisness... trust me, this stuff works. Only use it on the back side of the plastic. If you put it on the outside, when you paint over it the paint will have a chemical reaction and "spider". Before you apply it, rough up the area with some 220 grit sandpaper. Put down a couple coats letting it dry between applications and you are good to go!

#18

ill definitely do that. ive been getting some pretty good ideas from different people, so ill have to see what i can come up with.

#19

I sent my fairing out to them. They did a good job on the crack but the mounting hole was a mess in my opinion. Not round, square ,or in the right place. Others may think its ok but if you claim the repair will be better than new it should at lease be the right size and in the right place. When I called them on their poor work they said if I dont like it they will remove their work and send it back. I told them to do that and they changed their mind. So I told them to keep it and sell it on ebay. Anyone here have it ? lol.

#20

The ABS cement technique seems well worth investigating

http://www.migweb.co.uk/forums/styli...nt-bumper.html

kzrider.com - Plastic body panel repair. First Time.Forever!

Depends on what kind of plastic it is. Plastic welding is the best way. It fuses the pieces together without any glue nor does it need reinforcement. The repaired crack is usually stronger than the surrounding plastic. The welders are able to penetrate deeply for a thicker bond. It's really nothing more than a soldering iron or hot air gun and plastic rods of ABS Plastic to match your fairing. Rods are available for many kinds of plastic.

http://www.eastwood.com

http://www.urethanesupply.com/street.html

My motorcycle's fairing is made of ABS plastic. I've had good luck using ABS cleaner and glue (not PVC). The cleaner removes dirt and grease. Spread the edges apart and brush a little ABS cement into the crack. After it dries cover the crack with filler from an ABS repair kit, or dissolve ABS shavings into some ABS cement and make your own filler putty or, it's sold there, some JB Weld. After the filler dries grind it flush.

Coat the back of the repair area with JB Weld and a patch of wire or fiberglass window mesh to reinforce the repair. I lay a thin coat of JB Weld and press the screen mesh into it, then cover it with another coat of JB Weld. Just like working drywall. I also used two-part epoxy to reinforce a long crack. I laid a thick puddle of the epoxy over the crack, on the inside of the lower panel, and sunk short lengths of shirt hanger wire into that, across the crack line, for extra strength.

http://www.eastwood.com

http://www.urethanesupply.com/street.html

My motorcycle's fairing is made of ABS plastic. I've had good luck using ABS cleaner and glue (not PVC). The cleaner removes dirt and grease. Spread the edges apart and brush a little ABS cement into the crack. After it dries cover the crack with filler from an ABS repair kit, or dissolve ABS shavings into some ABS cement and make your own filler putty or, it's sold there, some JB Weld. After the filler dries grind it flush.

Coat the back of the repair area with JB Weld and a patch of wire or fiberglass window mesh to reinforce the repair. I lay a thin coat of JB Weld and press the screen mesh into it, then cover it with another coat of JB Weld. Just like working drywall. I also used two-part epoxy to reinforce a long crack. I laid a thick puddle of the epoxy over the crack, on the inside of the lower panel, and sunk short lengths of shirt hanger wire into that, across the crack line, for extra strength.

kzrider.com - Plastic body panel repair. First Time.Forever!

Last edited by Wicky; 01-08-2009 at 04:50 PM.

#21

i'm in the water biz, pumps to be exact. one of the sales reps i deal with is pretty much up to his ears in he plumbing biz. he has a zx10 and swears by abs cement. i too am a believer.

contrary to what i just said, last summer when i bought my hawk i noticed a crack in the tail section. i wanted it fixed NOW and only had epoxy. i put it on the inside and it worked good.

contrary to what i just said, last summer when i bought my hawk i noticed a crack in the tail section. i wanted it fixed NOW and only had epoxy. i put it on the inside and it worked good.

#23

#24

Nothing is beyond repair... but it may be beyond perfect repair. This is an extreme case, but ABS cement was the base for the repair.

A product called "Icing" was used on the paint side to smooth things out for painting. this pic doesn't do the damage justice.

(Don't mind the greasy finger smudges

Last edited by inderocker; 01-08-2009 at 08:00 PM.

#25

What ever you do. Dont use these guys.www.empiregp.com You will not be happy with their work.

#26

I beg to differ. They did a great job on my plastics. I sent them rashed and cracked stuff, dented tank, and multi color parts and the quality for the price can't be beat. I do have one mounting hole that shows a small flaw, but in 8000 miles it has held up just fine. Only I know it's there, and as picky as I am about my bikes I'm fine with it.

thanks for adding that Greg. I've heard mostly positive things about them. I have a small project (repaint only a couple of parts) I'm going to send them to give them a try and see what things look like before considering a bigger job.

#27

I debated whether I should even post, I do keep a eye on the forums but seldom post, I have done enough work here for the members to let it speak for its self, others can say more than I when it comes to whether someone is satisfied with what we charge for what we do.

I have posted the pictures of this part, while I am more than willing to work with someone who is not happy with something we have done I will not give in to a guy who has complained without even getting his part, the fact that the hole is oblong is not enough reason to say you are not happy with the part. When a part comes to us with a missing mounting hole the best I can do is try and guess where it used to be, the is no exact way to do this without mounting it on a bike, and this is not a option for me. My guess is that someone would rather have the part mount and have it a little bigger than not be able to line it up. I spent the time and the money to repair the part for him to ask for me to remove the work, the entire part had to be painted and cleared for free because of the shape of the mounting hole was ridiculous

I am going to commit a business no-no and be blunt and honest here. We enjoy what we do, there are three of us who work here, we are not above making a mistake we fix probably more bikes than any shop in the country, I do not expect perfection, I do try to make a reasonable effort to fix something if we did.

We are fortunate that we have plenty of work, enough so I can be choosy who I work for, I do not have to work for jerks, I try and provide a service that saves a guy money and gets his bike so it looks good again for less than he could by the part from the dealer, our goal is 50 percent of retail, if I can not save you that I will be up front and let you know that our service is not for you. If I think I can not make you happy I will also tell you to keep looking.

I do still have this part and it is for sale to anyone but the original owner...Bob

I have posted the pictures of this part, while I am more than willing to work with someone who is not happy with something we have done I will not give in to a guy who has complained without even getting his part, the fact that the hole is oblong is not enough reason to say you are not happy with the part. When a part comes to us with a missing mounting hole the best I can do is try and guess where it used to be, the is no exact way to do this without mounting it on a bike, and this is not a option for me. My guess is that someone would rather have the part mount and have it a little bigger than not be able to line it up. I spent the time and the money to repair the part for him to ask for me to remove the work, the entire part had to be painted and cleared for free because of the shape of the mounting hole was ridiculous

I am going to commit a business no-no and be blunt and honest here. We enjoy what we do, there are three of us who work here, we are not above making a mistake we fix probably more bikes than any shop in the country, I do not expect perfection, I do try to make a reasonable effort to fix something if we did.

We are fortunate that we have plenty of work, enough so I can be choosy who I work for, I do not have to work for jerks, I try and provide a service that saves a guy money and gets his bike so it looks good again for less than he could by the part from the dealer, our goal is 50 percent of retail, if I can not save you that I will be up front and let you know that our service is not for you. If I think I can not make you happy I will also tell you to keep looking.

I do still have this part and it is for sale to anyone but the original owner...Bob

#29

I have no idea what I charged the guy but you can have it shipped to your door for $125..

Thanks for the welcome, I am sure that this was not the best place to start out as a new member...Bob

Death Cattle this is a easy fix just go to our web site and click on the examples of repaired parts there are many there in worst shape than yours

Last edited by plasticweld; 01-09-2009 at 12:56 PM. Reason: more info

#30

Death Cattle, if you can paint this is your best option...RC